In modern industrial applications, standard specifications are often not enough. Projects in infrastructure, mining, oil & gas, marine, elevators, and heavy engineering frequently demand wire ropes that are tailored to specific operating conditions. This raises two critical questions for engineers and procurement teams: Can a wire rope be customized? And what lead time should one expect from a manufacturer in India?

The short answer is yes—wire ropes can be customized extensively when sourced from an experienced Wire rope manufacturer in India. From diameter and lay direction to core type and protective coatings, customization plays a crucial role in safety, performance, and lifecycle cost. This detailed guide explains how customization works, what options are available, and how lead times typically vary when working with a professional steel wire rope manufacturer in India.

Why Wire Rope Customization Matters in Industrial Applications

In real-world operating environments, wire ropes are rarely subjected to ideal or uniform conditions. Variables such as fluctuating loads, misalignment, environmental exposure, space constraints, and safety regulations all influence how a wire rope performs over time. This is why customization is not a luxury but a necessity for many critical applications.

When organizations work with an experienced Wire rope manufacturer in India, customization enables engineers to fine-tune rope performance to match exact operational demands rather than forcing equipment to adapt to standard products.

Customization directly impacts:

- Operational safety: Correct specifications reduce failure risks

- Equipment compatibility: Proper diameter and construction protect sheaves and drums

- Fatigue life: Optimized lay and core reduce internal stress

- Environmental resistance: Coatings and lubrication extend service life

- Regulatory compliance: Custom testing ensures standards are met

In sectors such as mining, cranes, oil & gas, and infrastructure, customization often determines whether a rope delivers years of reliable service or fails prematurely.

Customization Option 1: Wire Rope Diameter

How Diameter Impacts Performance

Wire rope diameter influences not only breaking strength but also bending efficiency, fatigue life, and equipment wear. Even small deviations in diameter can significantly affect rope performance.

A qualified Wire rope manufacturer in India produces wire ropes with tight dimensional tolerances, ensuring consistent interaction with sheaves, drums, and end fittings.

Engineering Considerations for Diameter Selection

Diameter customization becomes critical when:

- Existing equipment cannot be modified

- High safety factors are required for critical lifts

- Load cycles are frequent and continuous

- Regulatory codes specify minimum diameter-to-sheave ratios

Inadequate diameter selection can lead to accelerated wear, reduced fatigue life, and increased maintenance costs.

Industry Examples

- Precise diameter control is essential for Elevator Wire Ropes to ensure smooth ride quality

- Heavy-duty Crane Wire Ropes rely on optimized diameter-to-load ratios

Customization Option 2: Lay Direction and Lay Type

Understanding Lay Direction in Detail

Lay direction refers to the direction in which outer strands are twisted around the core. This characteristic directly influences rotation behavior, abrasion resistance, and handling characteristics.

An experienced steel wire rope manufacturer in India evaluates lay direction based on operational dynamics rather than defaulting to standard configurations.

Lay Types and Their Performance Impact

- Regular Lay: Offers better resistance to untwisting and is easier to inspect

- Lang Lay: Provides superior abrasion resistance and flexibility

Incorrect lay selection can cause rope rotation, uneven wear, or premature failure.

Application-Specific Lay Selection

- Non-Rotating Wire Ropes for crane hoisting

- Haulage Wire Ropes for mining transport systems

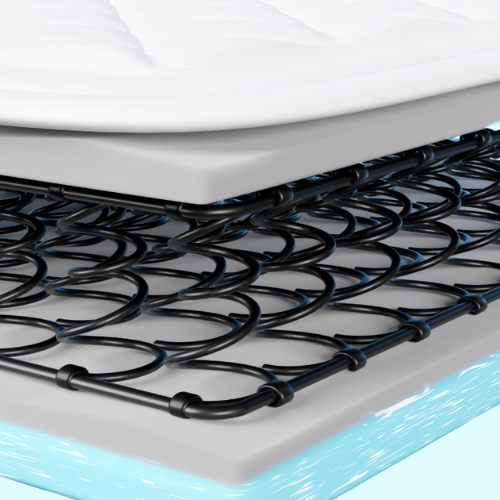

Customization Option 3: Core Type Selection

Why the Core Is Critical

The core acts as the foundation of a wire rope. It supports the strands, maintains rope geometry, and influences flexibility, load stability, and heat resistance.

A professional Wire rope manufacturer in India considers multiple operational variables when recommending a core type.

Core Types Explained

- Fiber Core (FC): High flexibility, shock absorption

- Wire Strand Core (WSC): Better crush resistance

- Independent Wire Rope Core (IWRC): Maximum strength and stability

Core Selection by Industry

- Mining Wire Ropes – IWRC for heavy loads

- Marine and Fishing Wire Ropes – Corrosion-resistant cores

- General Engineering Wire Ropes – Balanced performance

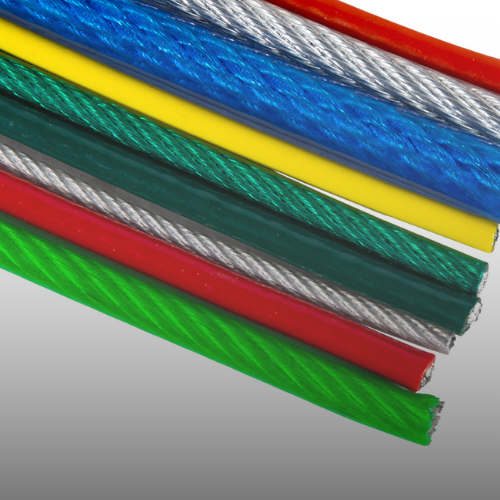

Customization Option 4: Coatings and Surface Protection

Environmental Challenges and Rope Degradation

Corrosion, abrasion, moisture, chemicals, and UV exposure are among the leading causes of wire rope failure. Surface protection is therefore a critical customization parameter.

A certified steel wire rope manufacturer in India applies coatings under controlled conditions to ensure uniform thickness and long-term adhesion.

Types of Coatings and Their Benefits

- Galvanized: Protection against atmospheric corrosion

- PVC / HDPE Coated: Enhanced moisture and chemical resistance

- Specialized Lubricants: Reduced internal friction and wear

Where Coatings Are Essential

Industry-Specific Customization Examples

Infrastructure and Suspension Systems

Large infrastructure projects such as bridges and aerial ropeways require highly customized solutions in terms of diameter, corrosion protection, and fatigue resistance.

Examples include: – Suspension Bridge Wire Ropes – Aerial Wire Ropes

Forestry, Marine, and Fishing

Outdoor applications demand abrasion resistance and environmental protection: – Forestry Wire Ropes – Marine and Fishing Wire Ropes

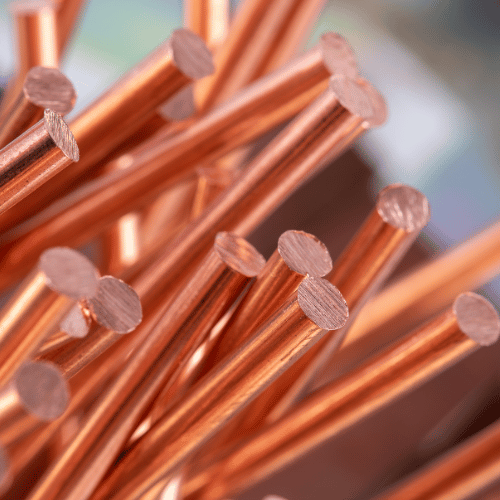

Quality Assurance in Customized Wire Ropes

Customization must never compromise quality. A trusted Wire rope manufacturer in India follows strict quality assurance processes, including material traceability, in-process inspections, and final testing.

Learn more about manufacturing controls on the Quality Assurance System page and compliance standards on the Certificates page.

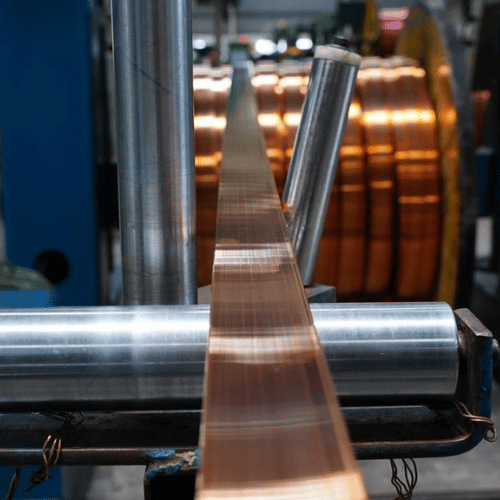

What Lead Time Should One Expect from a Manufacturer in India?

Lead time is a critical planning factor for EPC contractors, infrastructure developers, and procurement teams. While customization adds value, it also influences production schedules.

Key Factors That Influence Lead Time

A professional Wire rope manufacturer in India evaluates several parameters before committing to delivery timelines:

- Degree of customization (diameter, lay, core, coating)

- Availability of raw materials

- Production capacity and scheduling

- Testing, inspection, and certification requirements

- Project-specific documentation needs

Typical Lead Time Expectations

Based on industry experience, lead times generally fall into the following ranges:

- Standard wire ropes: 2–4 weeks

- Moderately customized wire ropes: 4–6 weeks

- Highly customized or project-specific ropes: 6–10 weeks

Engaging early with an established steel wire rope manufacturer in India helps avoid project delays.

How to Reduce Lead Time for Customized Wire Ropes

Procurement teams can reduce lead time by:

- Finalizing technical specifications early

- Sharing application details clearly

- Aligning standards and testing requirements upfront

- Working with manufacturers offering integrated testing and certification

Review available solutions and planning guidance on Our Products and Blogs.

Conclusion

Yes, wire ropes can be extensively customized to meet exact application requirements. From diameter and lay direction to core type and protective coatings, customization ensures optimal safety, performance, and service life.

By partnering with an experienced established steel wire rope manufacturer in India, organizations gain access to technical expertise, quality assurance, and predictable lead times—making customized wire ropes a practical and reliable choice for modern industrial projects.

To discuss customized wire rope requirements or understand lead times:

- Explore engineered solutions on the Wire Ropes page

- Browse application-specific options under Our Products

- Review quality and compliance on the Certificates page

- Stay informed with expert insights from Blogs

Connect with Bedmutha’s technical experts to design the right wire rope solution for your application.

Frequently Asked Questions (FAQs)

Can wire ropes be fully customized for specific applications?

Yes. Diameter, construction, lay direction, core type, and coatings can all be customized by a professional wire rope manufacturer.

Does customization increase cost significantly?

Customization may increase initial cost but usually reduces lifecycle cost by improving performance and service life.

What is the minimum order quantity for customized wire ropes?

This varies by manufacturer and construction. It is best to consult directly with a Wire rope manufacturer.

How long does it take to manufacture a customized wire rope?

Lead times typically range from 4 to 10 weeks depending on complexity and testing requirements.

Are customized wire ropes certified and tested?

Yes. Reputed manufacturers provide full testing and certification for customized products.