Wire ropes are critical load-bearing components used across industries such as construction, mining, oil & gas, marine, elevators, infrastructure, and general engineering. Their performance directly impacts safety, operational efficiency, and lifecycle costs. One of the most common questions asked by engineers and procurement professionals is: What is the service life of a wire rope, and how can it be effectively inspected for wear and damage?

The service life of a wire rope depends on multiple factors including design, application, operating conditions, maintenance practices, and inspection discipline. When sourced from a reliable Wire rope manufacturer in India, wire ropes are engineered to deliver predictable performance over extended periods—but only when they are correctly selected, installed, and maintained.

This comprehensive guide explains what determines wire rope service life, how to inspect wire ropes for wear and damage, and best practices followed by leading steel wire rope manufacturer in India facilities to ensure safety and reliability.

Understanding Wire Rope Service Life

Wire rope service life is best understood as a condition-based lifespan, not a fixed calendar duration. Unlike components that fail after a predictable time, wire ropes degrade progressively based on how they are used, loaded, and maintained.

A competent Wire rope manufacturer in India designs wire ropes with defined safety margins, fatigue resistance, and performance limits. However, the actual service life achieved in the field depends on operational discipline and inspection practices.

How Service Life Is Evaluated in Practice

Service life is typically assessed using a combination of:

- Number of operating cycles

- Cumulative load exposure

- Rate of wear and corrosion

- Visible and measurable damage indicators

Rather than asking how long a wire rope should last, engineers should focus on how the rope is performing under current operating conditions.

Key Factors That Influence Wire Rope Service Life

Several interrelated factors determine how long a wire rope will last:

- Load magnitude and frequency

- Bending cycles over sheaves and drums

- Abrasion and contact wear

- Environmental exposure (moisture, chemicals, salt)

- Quality of lubrication

- Installation accuracy

- Inspection frequency

Even the highest-quality products from a reputed steel wire rope manufacturer in India will experience reduced service life if these factors are not properly managed.

Typical Service Life Expectations by Application

There is no universal service life for wire ropes, but industry experience provides general benchmarks.

Cranes and Lifting Equipment

Crane wire ropes experience dynamic loads and repeated bending. With proper maintenance, Crane Wire Ropes can deliver long service life, but they require frequent inspection due to safety-critical usage.

Mining and Haulage Systems

Mining environments are abrasive and demanding. Mining Wire Ropes and Haulage Wire Ropes often have shorter service life due to continuous operation and harsh conditions.

Elevators and Aerial Applications

Elevator Wire Ropes and Aerial Wire Ropes are designed for smooth operation and fatigue resistance, offering predictable service life when inspected regularly.

Marine, Oil & Gas, and Forestry

Environmental exposure is the dominant factor in these applications. Corrosion-resistant Marine and Fishing Wire Ropes, Oil and Gas Wire Ropes, and Forestry Wire Ropes rely heavily on protective coatings and lubrication.

Why Regular Inspection Is Essential

Wire ropes rarely fail without warning. Progressive damage usually develops over time, making inspection the most effective tool for preventing accidents.

Organizations working with a trusted Wire rope manufacturer in India implement structured inspection programs to detect early signs of deterioration.

Benefits of Proper Inspection

- Prevents sudden failures

- Improves workplace safety

- Extends wire rope service life

- Reduces downtime and replacement costs

- Ensures compliance with safety regulations

How to Inspect a Wire Rope for Wear and Damage

Wire rope inspection involves visual observation, tactile examination, and operational monitoring carried out in a systematic and documented manner. Inspections should be conducted by trained personnel familiar with wire rope behavior.

1. Visual Inspection

Visual inspection is the first line of defense. Inspect the entire accessible length of the rope for:

- Broken wires

- Surface wear or abrasion

- Corrosion or rust scaling

- Deformation such as kinks or birdcaging

- Reduction in rope diameter

Special attention should be paid to high-stress areas such as terminations, sheave contact points, and drum crossover zones.

2. Broken Wire Evaluation

Broken wires are a key indicator of fatigue or abrasion. Standards specify allowable limits for broken wires over a given rope length. Exceeding these limits requires rope replacement.

3. Abrasion and Wear

Abrasion reduces wire diameter and strength. Excessive wear is common in applications such as General Engineering Wire Ropes and material handling systems.

4. Corrosion Damage

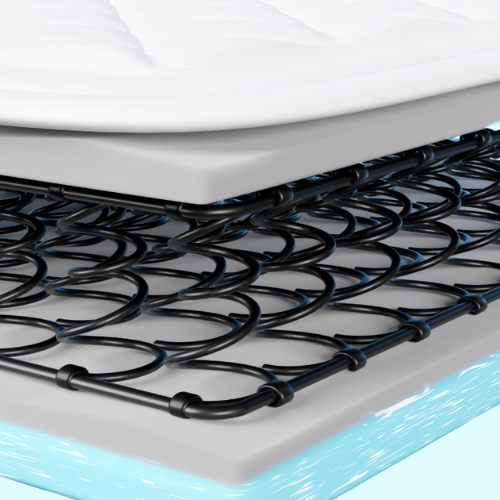

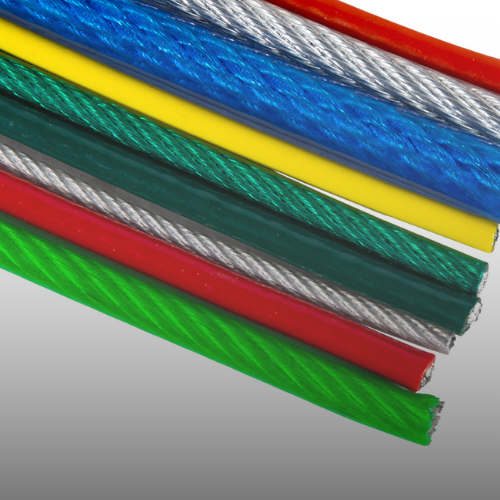

Corrosion may be external or internal. Internal corrosion is especially dangerous as it may not be visible. Using coated options such as PVC & HDPE Coated Wire Ropes helps mitigate this risk.

5. Deformation and Structural Damage

Kinks, crushing, or strand displacement indicate serious damage. Such defects compromise rope integrity and require immediate replacement.

Inspection Frequency Guidelines

Inspection frequency depends on application severity, risk level, and regulatory requirements:

- Daily visual checks for cranes and lifting equipment

- Weekly inspections for continuous-duty systems

- Periodic detailed inspections by qualified personnel

High-risk applications such as Non-Rotating Wire Ropes and suspension systems demand stricter inspection schedules.

The Role of Lubrication in Extending Service Life

Lubrication reduces internal friction, prevents corrosion, and slows wear. A reputable steel wire rope manufacturer in India recommends lubrication practices tailored to rope construction and environment.

Regular lubrication is particularly important for ropes used in Suspension Bridge Wire Ropes and offshore applications.

When Should a Wire Rope Be Replaced?

A wire rope must be removed from service when inspection results clearly indicate unacceptable deterioration:

- Broken wire limits are exceeded

- Severe corrosion is present

- Diameter reduction exceeds allowable limits

- Deformation or core damage is observed

Delaying replacement increases the risk of catastrophic failure.

Quality Assurance and Certification

Reputed manufacturers follow strict quality systems to ensure consistent performance. Learn more about testing and controls under the Quality Assurance System and compliance on the Certificates page.

Conclusion

The service life of a wire rope is not fixed—it is determined by how well the rope is selected, installed, inspected, and maintained. By understanding wear mechanisms and implementing disciplined inspection practices, organizations can significantly extend rope lifespan and improve safety.

Partnering with a reliable Wire rope manufacturer in India and experienced steel wire rope manufacturer in India ensures access to high-quality products, technical guidance, and proven quality systems—making wire rope inspection and maintenance a strategic advantage rather than a reactive task.

Learn More

To select the right wire rope and ensure long service life:

- Explore engineered solutions on the Wire Ropes page

- Browse application-specific options under Our Products

- Review quality systems and certifications on Quality Assurance System and Certificates

- Stay informed with technical updates from Blogs

Connect with Bedmutha’s experts for guidance on inspection, maintenance, and replacement strategies.

Frequently Asked Questions (FAQs)

How long does a wire rope typically last?

Service life varies by application and maintenance, ranging from months in harsh mining environments to several years in controlled elevator systems.

What is the most common cause of wire rope failure?

Fatigue due to repeated bending and improper maintenance is the most common cause.

Can lubrication really extend wire rope life?

Yes. Proper lubrication significantly reduces wear and corrosion.

Are all broken wires a reason for replacement?

No, but exceeding allowable limits requires immediate replacement.