Introduction – Why Core Type Matters in Wire Rope Performance

In the world of lifting, hoisting, and heavy-duty engineering, choosing the right type of wire rope can make or break your project’s success. While most buyers focus on rope diameter and construction, it’s actually the core—the central element—that defines its strength, flexibility, and durability.

As a leading manufacturer of wire ropes in India, Bedmutha Industries understands that every application demands a specific core design. Whether you’re constructing a bridge, operating cranes, or managing marine lifting systems, the choice between Steel Wire Rope (IWRC) and Fibre Core (FC) determines long-term performance and safety.

This detailed guide compares FC vs IWRC wire ropes, explaining their composition, differences, and the right choice for your application—straight from India’s trusted wire rope manufacturer.

What is a Fibre Core (FC) Rope? – Flexibility Meets Smooth Performance

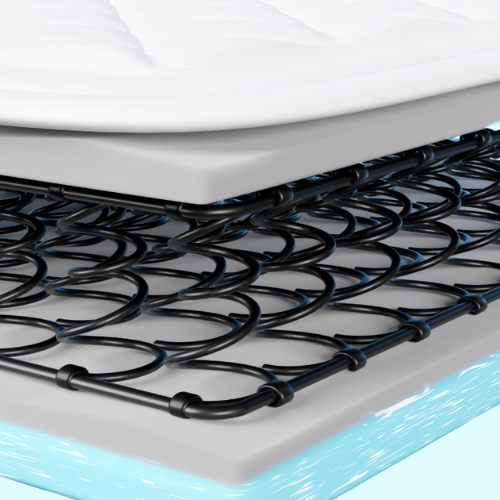

A Fibre Core wire rope is designed with a natural or synthetic fibre center, typically made of materials such as sisal, manila, or polypropylene. This type of core provides the rope with exceptional flexibility and shock absorption.

Composition & Characteristics

- Central core made from natural or synthetic fibres

- Excellent bending fatigue resistance

- Lightweight and easy to handle

- Retains lubricants effectively, reducing internal wear

The flexible nature of FC ropes allows them to perform smoothly around pulleys, drums, and sheaves, making them ideal for lighter operations.

Advantages of Fibre Core Ropes

- Superior Flexibility – Perfect for applications requiring frequent bending.

- Smoother Operation – Reduces vibration and mechanical stress.

- Corrosion Resistance – Fibre material is less prone to rusting.

- Lightweight Handling – Easier installation and maintenance.

Applications of Fibre Core Ropes

Fibre core ropes are well-suited for light- to medium-duty operations such as:

- Elevators and Lifts – Provides smooth traction and quiet operation (Elevator Ropes)

- Marine and Fishing Equipment – Excellent in moist environments (Marine & Fishing)

- Forestry Applications – Handles vibration and impact well (Forestry Ropes)

- Barrier and Guardrail Systems – Absorbs energy effectively (Barrier Wire Ropes)

For industries prioritizing flexibility and smoother movement, fibre core ropes are a reliable option.

What is an Independent Wire Rope Core (IWRC)? – Strength Beyond Comparison

An Independent Wire Rope Core (IWRC) replaces the fibre core with a steel wire rope core. This structure drastically enhances the rope’s tensile strength, load-bearing capacity, and resistance to crushing.

Composition & Features

- Central core made of steel strands twisted into a mini rope

- Designed to withstand heavy loads

- High resistance to heat, abrasion, and crushing

- Offers better dimensional stability

IWRC ropes, also known as steel core wire ropes, are preferred in applications where strength, temperature resistance, and longevity are non-negotiable.

Advantages of IWRC Ropes

- Superior Load Capacity – Handles extreme tension and pressure.

- High-Temperature Resistance – Performs well in hot industrial environments.

- Durability – Longer lifespan and reduced deformation.

- Less Elongation – Provides stability during long-term use.

Applications of IWRC Ropes

IWRC ropes are designed for heavy-duty applications including:

- Cranes & Hoists – Handles heavy lifting (Crane Ropes)

- Mining Operations – Endures abrasion and stress (Mining Ropes)

- Oil & Gas Exploration – Performs under pressure (Oil & Gas Ropes)

- Bridge and Infrastructure Projects – Ensures stability (Suspension Bridges)

For industries prioritizing maximum strength, safety, and reliability, IWRC ropes are the preferred solution.

IWRC vs FC Wire Rope: Key Differences You Should Know

Choosing between Fibre Core and Independent Wire Rope Core depends on your project’s operational needs. Below is a clear comparison to help you decide:

|

Feature |

Fibre Core (FC) |

Independent Wire Rope Core (IWRC) |

|

Core Material |

Natural/Synthetic Fibre |

Steel Wire Rope |

|

Flexibility |

High |

Moderate |

|

Strength |

Lower |

Higher |

|

Weight |

Light |

Heavy |

|

Crushing Resistance |

Limited |

Excellent |

|

Temperature Resistance |

Poor |

Excellent |

|

Lubrication Retention |

High |

Moderate |

|

Service Life |

Shorter |

Longer |

|

Cost |

More Affordable |

Premium Investment |

In short:

- Choose FC ropes for flexibility and smooth operation.

- Choose IWRC ropes for strength, heat resistance, and longevity.

How a Trusted Wire Rope Manufacturer Ensures Core Quality

A reputable wire rope manufacturer like Bedmutha Industries doesn’t just produce ropes—it engineers performance and reliability from the inside out.

1. Material Excellence

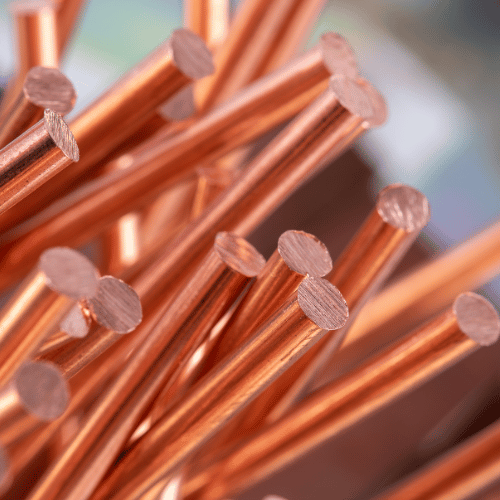

Every rope begins with premium-grade steel wire rods or tested synthetic fibres. Bedmutha’s strict material sourcing ensures consistent quality and compliance with global safety standards.

2. Precision Manufacturing

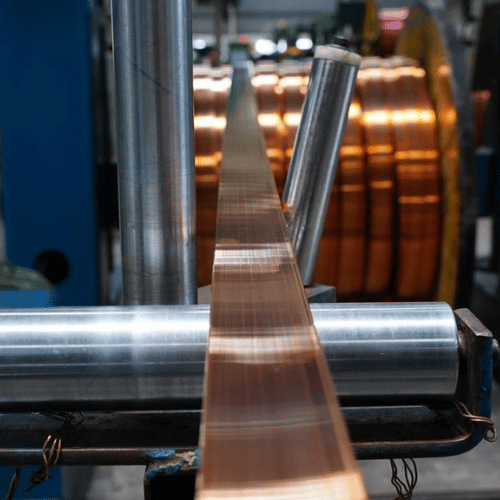

Under its Sure Wire Ropes brand, Bedmutha utilizes state-of-the-art machinery for stranding and closing. This ensures accurate layering, balanced tension, and superior load distribution—crucial for both IWRC and FC wire ropes.

3. Lubrication & Coating Process

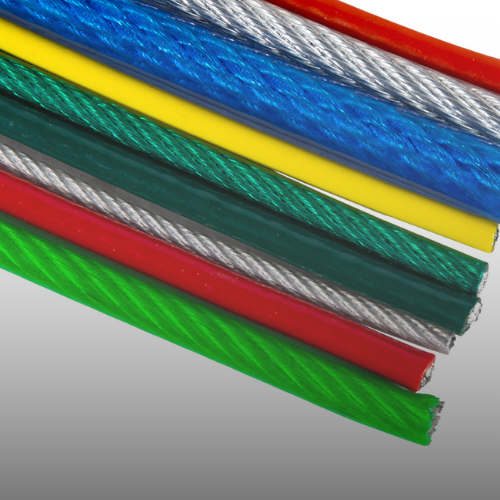

Each core—whether steel or fibre—is lubricated and coated for corrosion resistance. For marine or outdoor use, PVC/HDPE coatings (PVC/HDPE Coated Ropes) provide additional protection against moisture, chemicals, and abrasion.

4. Testing & Quality Control

Every batch of wire ropes undergoes tensile, bend, and fatigue testing. Bedmutha adheres to ISO and BIS-certified standards, ensuring that every rope meets industry safety and performance benchmarks.

By combining engineering precision with advanced testing, Bedmutha positions itself as India’s trusted wire rope manufacturer for both domestic and international markets.

Applications Best Suited for Each Rope Type

Industry/Application | Recommended Rope Type | Reason |

Elevators and Lifts | Fibre Core | Smooth and flexible operation |

Marine/Fishing | Fibre Core | Water and corrosion resistance |

Forestry/Barrier Use | Fibre Core | Shock absorption |

Cranes & Hoists | IWRC | High load capacity |

Mining Operations | IWRC | Strength and durability |

Oil & Gas | IWRC | Heat and chemical resistance |

Bridge/Infrastructure | IWRC | Stability under tension |

Final Verdict – Choosing Between FC and IWRC Ropes

Both Fibre Core and Steel Core (IWRC) wire ropes play vital roles in industrial applications. The choice depends on your project’s load, environment, and safety demands.

- Opt for Fibre Core ropes when flexibility, smooth movement, and light handling are your priorities.

- Choose IWRC ropes when strength, heat resistance, and long life matter most.

As a leading manufacturer of wire ropes, Bedmutha Industries ensures that every Sure Wire Rope is built to international standards—engineered for strength, tested for reliability, and trusted by industries across construction, mining, marine, and oil & gas sectors.

👉 View our complete Steel Wire Rope range

👉 Contact Bedmutha Industries today for a customized quotation or technical consultation.