Introduction

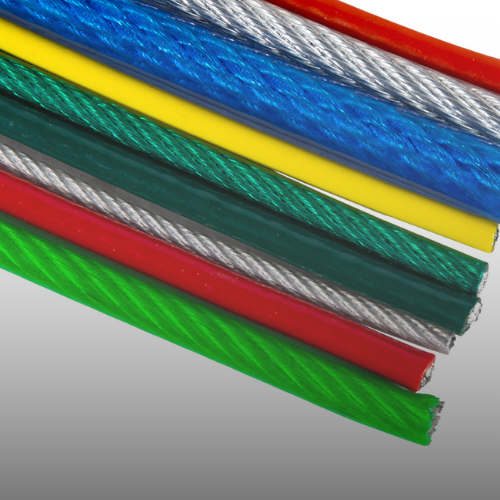

A wire rope may look simple, but its safety depends on hundreds of tiny strands working in harmony. Before it reaches a construction site or mine, it undergoes a series of stringent tests. Here’s a deep dive into the quality tests followed by reputed manufacturers of wire rope in India.

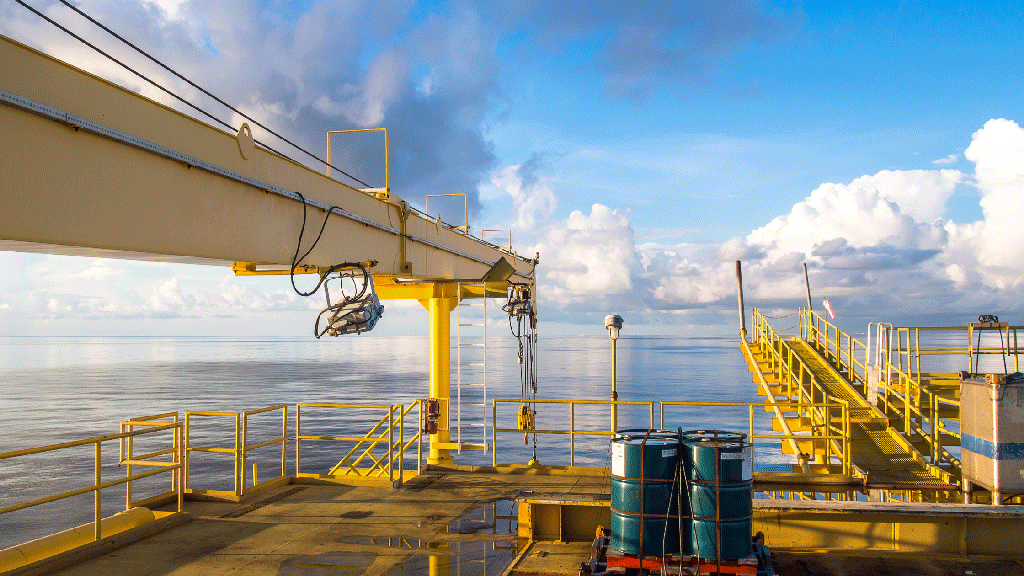

Manufacturing high-performance wire ropes is only half the battle. The other half lies in verifying every meter of rope to ensure it can meet real-world demands. Especially in sectors like mining, cranes, elevators, and marine, failure is not an option. That’s where wire rope testing ibecomes not just important, but essential.

Mechanical Tests – Breaking Load, Tensile Strength, Elongation

Mechanical wire rope testing forms the foundation of quality assurance. These tests validate the rope’s structural integrity and performance under various loads.

Breaking Load Test:

- Measures the maximum load a rope can handle before it snaps.

- Essential for defining the rope’s safe working load (SWL).

- Conducted using calibrated tensile testing machines.

Tensile Strength Test:

- Evaluates the strength of the individual wires within the rope.

- Ensures consistency across wire batches used in rope construction.

Elongation Test:

- Assesses how much a rope stretches under load.

- Critical for precision applications like elevators and cranes.

Reputable manufacturers of wire rope like Bedmutha Industries carry out these wire rope testing standards in certified in-house labs using IS and ISO-compliant equipment.

Fatigue and Bending Tests in Wire Rope Testing India

Wire ropes used in dynamic environments face repeated bending and load cycles. Fatigue resistance is crucial in wire rope testing India protocols.

Fatigue Testing:

- Simulates repeated loading cycles over pulleys or sheaves.

- Tests the rope’s lifespan under repetitive bending stress.

- Applied especially for hoisting, mining, and dragline ropes.

Reverse Bend and Torsion Tests:

- Evaluates flexibility and internal stress behavior.

- Checks rope’s resistance to twisting and repeated direction changes.

Bedmutha’s elevator rope range undergoes rigorous fatigue analysis to ensure reliability in high-stress environments.

Non-Destructive and Visual Inspection Methods in Wire Rope Testing India

In addition to destructive testing, several non-destructive tests (NDT) and inspections are performed as part of wire rope testing in India to detect flaws before dispatch.

Magnetic Flaw Detection:

- Detects internal wire breaks or flaws not visible externally.

- Helps prevent sudden failures in operation.

Visual Inspection:

- Surface defects, broken wires, corrosion, birdcaging, or flattening.

- Used to assess overall workmanship and rope condition.

Diameter and Lay Length Check:

- Ensures rope matches dimensional specifications.

- Verifies uniformity and construction geometry.

High-quality manufacturers of wire rope like Bedmutha integrate these checks as part of their final QA before packaging.

Testing Frequency and IS 2266 Compliance for Wire Rope Testing India

IS 2266 is the Indian Standard that governs the specifications for wire ropes in general engineering applications. Wire rope testing in India follows this compliance.

Key Compliance Factors:

- Each batch must undergo mechanical and dimensional tests.

- Sample frequency depends on rope diameter and application category.

- Rope constructions must match IS-defined configurations (e.g., 6×19, 6×36).

- Lubrication, galvanization, and core type must be documented.

Bedmutha adheres to IS 2266, IS 2365 (elevator ropes), and international equivalents, ensuring global-standard wire rope testing India compliance.

How Manufacturers in India Ensure Traceability in Wire Rope Testing

Traceability is critical to ensuring quality, accountability, and customer confidence as part of the wire rope testing India protocol.

Methods:

- Unique batch numbers marked on each coil.

- Test certificates linked to rope serial numbers.

- Digital records of test results, material inputs, and production logs.

Leading manufacturers of wire rope use ERP and SPC software to maintain traceable quality control. At Bedmutha, every wire rope is accompanied by a complete traceability document.

Why Bedmutha Industries is Known for Stringent QA/QC in Wire Rope Testing India

Bedmutha Industries, a trusted manufacturer of wire rope, sets benchmarks in India for wire rope testing and certification:

- Fully-equipped testing labs for tensile, elongation, fatigue, and NDT.

- ISO 9001, 14001, 45001, and IATF 16949 certifications.

- Wire ropes exported to 21+ countries with globally accepted test documentation.

- Application-specific testing for mining, cranes, elevators, marine, and suspension bridges.

- Transparent quality assurance processes backed by certified professionals.

When safety is non-negotiable, Bedmutha ensures every rope is tested — not assumed.

Conclusion – Only tested ropes build safe projects

In India’s demanding industries, every wire rope must meet the challenge — not just in design, but in verified performance. Through mechanical, fatigue, non-destructive, and IS-compliant testing, manufacturers of wire rope guarantee that what reaches the field is built for trust.

For high-performance, tested, and traceable ropes, Bedmutha Industries stands as a leading manufacturer of wire rope and expert in wire rope testing India.