Introduction

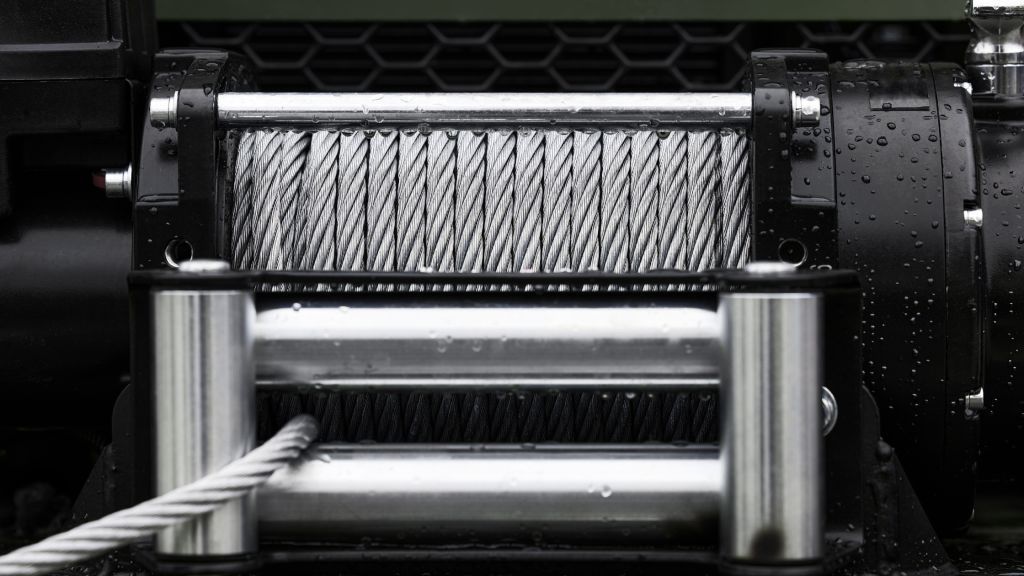

Wire ropes are the backbone of industries ranging from construction, mining, marine, elevators, and industrial machinery. They are not merely twisted wires but are highly engineered systems designed to lift, pull, and support loads safely and efficiently. Selecting the right rope requires more than just knowing the diameter or material; it demands a solid understanding of the terminology, construction, performance metrics, and safety considerations.

For procurement managers, engineers, and decision-makers, knowing these terms ensures you communicate specifications accurately with wire rope manufacturers in India, avoid costly mistakes, and select ropes that meet operational demands. In this guide, we will provide a detailed explanation of all essential wire rope terminology, helping you make informed decisions for your projects.

1. Basic Wire Rope Terms

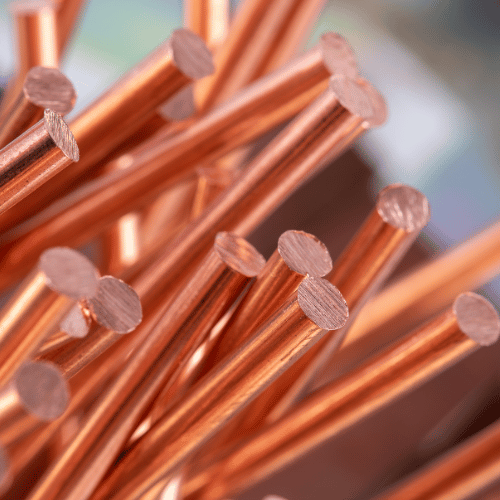

Wire

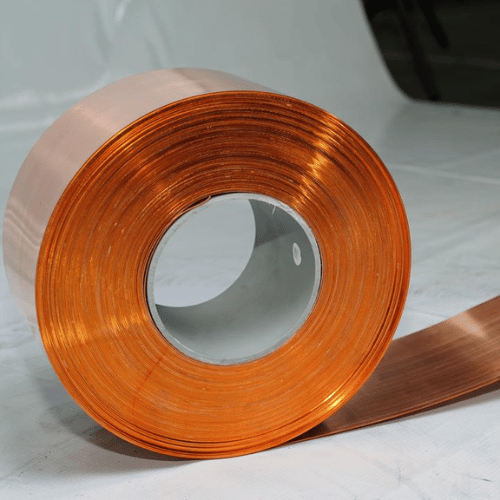

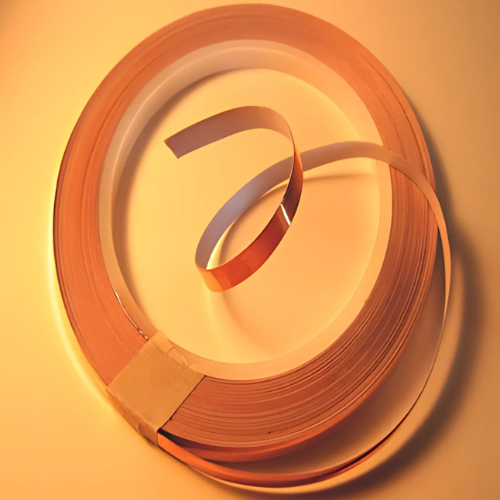

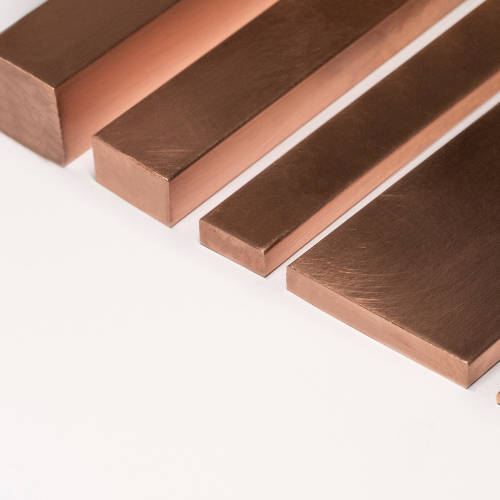

A wire is the fundamental unit of any rope. It is usually made from high-carbon steel or specialized alloys, providing the tensile strength needed to lift and hold heavy loads. The diameter, flexibility, and coating of each wire influence the overall performance and lifespan of the rope. For instance, marine ropes need galvanized or PVC-coated wires to resist corrosion. Choosing high-quality wire is crucial for applications like elevator wire ropes, where safety cannot be compromised.

Strand

A strand consists of multiple wires twisted together. The number of wires and the pattern in which they are laid determine flexibility, abrasion resistance, and load-bearing capacity. Typical constructions like 6×19 or 6×36 balance flexibility and strength. Strand construction directly affects the rope’s suitability for applications like mining haulage, cranes, or industrial lifting. A poorly designed strand can lead to premature wear or breakage under stress.

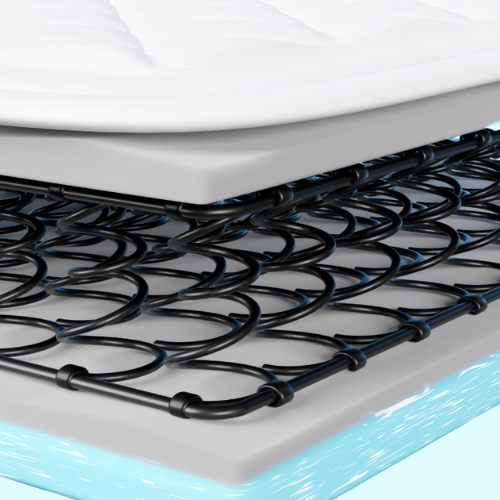

Core

The core provides support and stability to the rope. There are three main types:

- Fiber Core (FC): Flexible and capable of holding lubricant; ideal for light-duty applications and easy bending.

- Independent Wire Rope Core (IWRC): Made of steel, providing maximum strength; widely used in heavy lifting, mining, and elevator operations.

- Wire Strand Core (WSC): Combines the strength of steel with some flexibility for moderate loads.

Choosing the correct core type is critical to ensure the rope performs reliably under the specific loads and conditions it will face.

Lay

The lay describes the direction of wire and strand twisting. Two common types are:

- Regular Lay: Wires in the strand twist one way, strands twist the opposite way. Provides balanced wear resistance and is suitable for general lifting.

- Lang Lay: Wires and strands twist in the same direction. Offers higher fatigue resistance and flexibility, often used in haulage ropes, cranes, and mining ropes.

The lay type affects flexibility, rotation, and wear characteristics of the rope.

Rope Diameter

The rope diameter is fundamental for determining load capacity. A rope that is too thin may fail under load, while a rope that is too thick may be unnecessarily heavy and costly. Accurate measurement ensures that ropes meet design specifications, particularly in critical applications like elevators or high-strength steel wire ropes in India.

2. Wire Rope Construction & Types

Wire rope construction impacts performance, durability, and suitability for specific tasks.

Common Constructions

- 6×19 Construction: Offers a balance between flexibility and strength, commonly used in cranes, elevators, and hoisting equipment. It provides moderate wear resistance and good handling characteristics.

- 6×36 Construction: Designed for higher fatigue resistance, making it ideal for dynamic applications such as mining shafts, offshore rigs, and aerial lifts.

Specialized Constructions

- Non-Rotating Ropes: Designed to minimize rotation under load, preventing equipment twisting and ensuring safety in lifting operations. These ropes are essential for high-rise elevators and high-rise cranes, where stability and precision are critical

- Compacted Ropes: Wires are compressed to increase strength, wear resistance, and surface smoothness. Used extensively in cranes, industrial lifting, and heavy-duty construction operations.

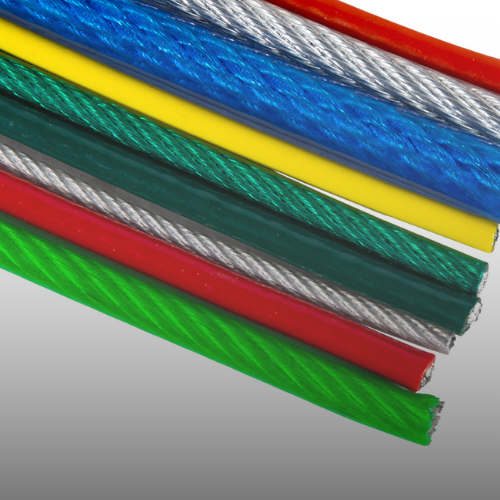

Coatings and Treatments

- Galvanized Wire Ropes: Provide superior corrosion resistance in marine, coastal, or outdoor environments.

- PVC/HDPE Coated Ropes: Additional layers protect against abrasion, chemicals, and harsh conditions, enhancing lifespan in industrial applications.

These constructions are offered by leading wire rope manufacturers India, ensuring that ropes meet stringent operational standards.

3. Performance & Strength Terminology

Understanding performance metrics is essential to select ropes that meet operational and safety standards.

Tensile Strength

This measures the maximum stress a rope can withstand before failure. High tensile strength is critical for construction cranes, mining haulage, and elevator ropes. It ensures the rope can handle heavy loads without elongation or snapping.

Breaking Load

The breaking load is the exact force at which a rope will fail. Engineers apply a safety factor, typically 4 to 6 times the working load, to ensure the rope operates within safe limits. Using ropes below recommended specifications can lead to premature failures and increased risk.

Fatigue Resistance

Ropes undergo repeated bending and stress. Fatigue resistance indicates how well the rope tolerates these cycles without developing internal fractures. Ropes with high fatigue resistance are essential in mining shafts, hoisting, and crane operations where ropes are in constant motion.

Lubrication

Lubrication reduces friction between wires, prevents internal corrosion, and extends service life. Modern steel wire rope manufacturers in India provide pre-lubricated ropes for easier maintenance and higher durability.

Rotation Resistance

Ropes under load may twist or rotate. Rotation-resistant ropes prevent twisting, providing safer operations in elevators, cranes, and hoists. Non-rotating ropes are specifically engineered for such requirements.

4. Application-Specific Terms

Wire ropes are designed for specific industries and applications.

Haulage Ropes

Used in mining and construction to transport heavy loads along shafts or inclined surfaces. The rope must withstand high tensile loads and abrasion. Check Haulage Ropes for detailed specifications.

Aerial Ropes

Support cable cars, funiculars, and ski lifts. Must resist stretch and handle environmental stress, ensuring passenger safety. See Aerial Ropes.

Elevator Ropes

Elevator ropes are designed for human safety, requiring strict adherence to tensile strength, rotation resistance, and fatigue standards. Refer to Elevator Ropes.

Mining Ropes

Used for underground haulage and lifting. Must withstand high abrasion and frequent bending. More at Mining Ropes.

Marine & Fishing Ropes

Exposed to saltwater and humid conditions, requiring galvanization or coatings for long-term durability. Visit Marine Ropes.

Slings & Fittings

Used for hoisting and rigging, compatible with specific rope types. Regular inspections ensure safety. See Slings & Fittings.

5. Inspection & Safety Terminology

Safety inspections are critical to prevent accidents and maintain rope integrity.

Wear & Abrasion

Wear indicates reduced rope strength. Continuous monitoring and maintenance prevent operational hazards.

Birdcaging

Occurs when strands separate into a cage-like formation. Requires immediate rope replacement to avoid failure.

Corrosion

Rust weakens steel, reducing tensile strength. Galvanized and coated ropes are preferred in corrosive environments.

Broken Wires

Even a single broken wire can compromise rope safety. Regular checks, especially for elevator ropes, prevent accidents.

Rope Discard Criteria

Rope retirement guidelines dictate when a rope should be discarded. Adherence ensures workplace safety and regulatory compliance.

6. Additional Technical Terms

- Core Diameter: Measures the rope’s central core thickness, impacting load distribution.

- Lay Length: The distance required for a strand to complete one full twist.

- Pitch: Distance between wire intersections in a strand.

- Seizing: Binding rope ends to prevent unraveling.

- Lubricant Penetration: Ensures lubrication reaches the core for optimal corrosion protection.

7. Why Terminology Matters

- Accurate Specification: Ensures precise rope selection from wire rope suppliers in India.

- Cost Savings: Avoids unnecessary over-specification and replacements.

- Operational Safety: Reduces accidents and equipment damage.

- Effective Communication: Aligns engineers, suppliers, and operators on technical requirements.

8. Choosing the Right Wire Rope Manufacturer

Key considerations include:

- Certifications & Quality Standards: ISO, BIS, and international compliance.

- Product Range: Elevator, mining, marine, industrial ropes.

- Customization: Diameter, construction, coatings, and core options.

- After-Sales Support: Inspection guidance, maintenance, and technical assistance.

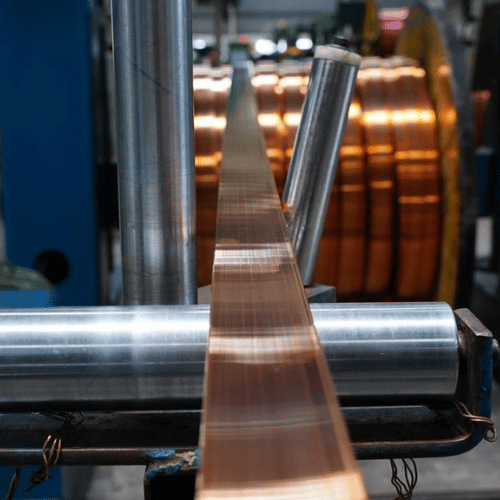

Why Choose Bedmutha Industries – A Trusted Wire Rope Manufacturer in India

When selecting a wire rope manufacturer in India, decision-makers need more than just product availability—they need assurance of quality, consistency, and deep technical expertise. Bedmutha Industries stands out as one of the most reliable and innovative wire rope manufacturers in India, offering a comprehensive range under the brand Sure Wire Ropes.

With state-of-the-art manufacturing capabilities and adherence to global quality standards, we deliver steel wire ropes engineered for the toughest applications—be it mining, construction, elevators, marine, or oil & gas. Our in-depth understanding of wire rope terminology, construction nuances, and industry-specific demands ensures every product is optimized for safety, performance, and longevity.

Whether you need non-rotating ropes for elevators, galvanized marine ropes, or high-tensile mining haulage ropes, Bedmutha offers tailored solutions with unmatched technical support and product reliability.

Conclusion

A thorough understanding of wire rope terminology empowers professionals to choose the right ropes for construction, mining, elevators, marine, and industrial projects. From basic components to application-specific ropes, performance metrics, and safety terms, this knowledge ensures cost-effective, safe, and reliable operations.

🏗️ Explore Our Full Range of Steel Products at Bedmutha Industries :