Introduction

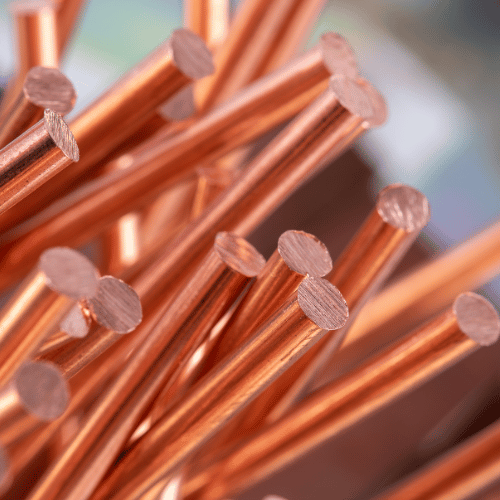

Steel wire ropes are the backbone of numerous heavy-duty industries — from construction, mining, and oil & gas to marine, elevators, and suspension bridges. Their role in ensuring safety, reliability, and operational efficiency cannot be overstated. In industries where safety margins are slim and the consequences of failure can be catastrophic, wire ropes stand as silent guardians, carrying immense loads, providing structural stability, and enabling smooth transportation systems.

As a leading wire rope manufacturer in India, Bedmutha Industries offers high-performance Sure Wire Ropes that are engineered to withstand tough environments and rigorous use. Whether it’s a crane hoisting tons of material, an offshore rig operating in saline conditions, or a suspension bridge enduring constant environmental stress, wire ropes are central to operational safety.

But even the strongest ropes need proper care. Without correct selection, handling, and maintenance, their service life can be drastically shortened. This not only increases costs but also poses safety risks. That’s why understanding best practices to extend the life of steel wire ropes is crucial for engineers, procurement managers, and decision-makers.

Introduction

Steel wire ropes are the backbone of numerous heavy-duty industries — from construction, mining, and oil & gas to marine, elevators, and suspension bridges. Their role in ensuring safety, reliability, and operational efficiency cannot be overstated. In industries where safety margins are slim and the consequences of failure can be catastrophic, wire ropes stand as silent guardians, carrying immense loads, providing structural stability, and enabling smooth transportation systems.

As a leading wire rope manufacturer in India, Bedmutha Industries offers high-performance Sure Wire Ropes that are engineered to withstand tough environments and rigorous use. Whether it’s a crane hoisting tons of material, an offshore rig operating in saline conditions, or a suspension bridge enduring constant environmental stress, wire ropes are central to operational safety.

But even the strongest ropes need proper care. Without correct selection, handling, and maintenance, their service life can be drastically shortened. This not only increases costs but also poses safety risks. That’s why understanding best practices to extend the life of steel wire ropes is crucial for engineers, procurement managers, and decision-makers.

Why Rope Life Extension Matters

- Safety & Reliability: Rope failure can lead to downtime, equipment damage, or even accidents. For instance, in a mining operation, a rope failure during haulage can halt production, endanger workers, and damage expensive machinery. In elevators, a malfunctioning rope can put lives at risk, making safety non-negotiable.

- Cost Efficiency: Extending rope life reduces frequent replacements, saving material and labor costs. A well-maintained rope in a port crane can save thousands annually by reducing downtime and preventing emergency purchases.

- Operational Performance: Well-maintained ropes perform consistently, ensuring smooth operations. In industries where continuity is key, such as oil drilling, even minor disruptions can result in massive financial losses. Ropes that are cared for properly provide reliability and peace of mind.

Bedmutha’s Sure Wire Ropes are designed with precision, and when combined with correct practices, they can deliver long-lasting performance across industries. You can explore our full range of wire ropes to see their diverse applications.

Best Practices for Extending the Life of Steel Wire Ropes

1. Choose the Right Rope for the Job

Selecting the correct type of rope is the foundation of longevity. Each application places unique demands on wire ropes:

- Application-specific ropes: Mining ropes are engineered for abrasion and heavy loads, while elevator ropes are optimized for flexibility and safety. For instance, using an elevator rope in mining would lead to rapid wear as it is not designed for abrasive dust or impact loads.

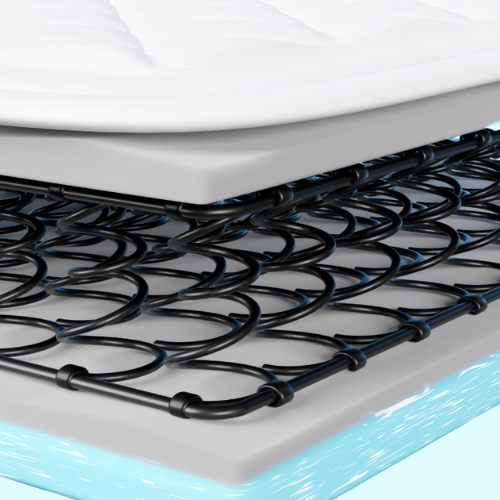

- Core selection: Steel cores (IWRC/WSC) offer higher strength and crush resistance, essential for crane ropes. Fiber cores, on the other hand, provide better flexibility, making them suitable for lighter tasks where bending fatigue is more critical than sheer strength.

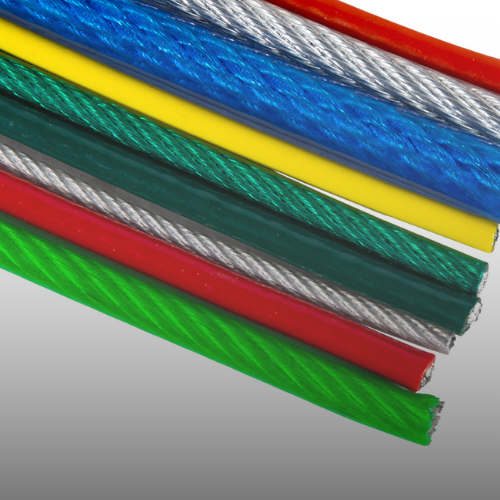

- Coatings: In corrosive environments, PVC/HDPE coated ropes add an extra layer of protection, slowing rust formation and extending service life. In marine conditions, this can mean the difference between a rope lasting years versus months.

Case Example: Offshore oil rigs rely on oil & gas ropes with corrosion-resistant coatings. A rig that used uncoated ropes saw replacements required every 8 months, while coated ropes extended service life to over 18 months.

2. Correct Installation Practices

Even the best rope can fail prematurely if installed incorrectly. Proper installation ensures the rope starts its service life under optimal conditions:

- Avoid twist or torque: Twisted ropes during installation create internal stress. For example, in aerial tramways, misalignment caused by torque leads to uneven wear and sudden rope snapping.

- Apply uniform tension: The first layer on the drum must be wound tightly to provide a strong foundation. Without this, subsequent layers dig into the lower layers, causing crushing and internal wire damage.

- Correct alignment: Sheaves and drums must be perfectly aligned. A misaligned sheave increases bending stress, which significantly shortens rope life.

- Sheave diameter: Using too small a sheave increases bending stress on the rope, leading to fatigue cracks. For heavy cranes, larger sheaves dramatically extend rope lifespan.

Bedmutha’s haulage ropes and aerial ropes are engineered to withstand demanding installation environments, ensuring smooth spooling and minimal internal stress.

3. Regular Lubrication and Cleaning

Lubrication is not optional — it is essential to rope longevity:

- Clean before lubrication: Dirt, dust, and hardened grease act like sandpaper, grinding down the rope’s surface. Cleaning with a wire brush or compressed air removes debris before fresh lubricant is applied.

- Use penetrating lubricants: These reach the rope’s core, reducing internal wire-on-wire friction and preventing dry spots where fatigue develops.

- Environmental considerations: In marine and fishing industries, marine ropes require frequent lubrication with anti-corrosion oils. For offshore applications, environmentally friendly lubricants reduce ecological impact.

Industry Note: A port operator in Singapore reduced rope replacement frequency by 35% after introducing scheduled cleaning and lubrication programs tailored for tropical humidity.

4. Avoid Mechanical Damage

Ropes are tough but vulnerable to mishandling. Mechanical damage often leads to early retirement:

- Never drag ropes on rough surfaces: Dragging across concrete or steel floors strips protective coatings and weakens outer wires.

- Prevent kinking or bird-caging: Mishandling during reeving causes permanent deformation. Once bird-caging occurs, the rope must be replaced immediately.

- Avoid shock loading: A sudden load increase — like a crane lifting beyond capacity — can cause invisible internal fractures, making the rope unsafe.

- Check sheave grooves: Worn or undersized grooves pinch the rope, accelerating wear.

In forestry operations, forestry ropes face heavy mechanical stress. Avoiding improper handling practices here can double rope lifespan.

5. Scheduled Inspections and Monitoring

Routine inspections are the backbone of preventive maintenance:

- Check for broken wires, corrosion, or wear: Broken wires often cluster in high-stress points.

- Measure rope diameter: Diameter reduction signals core failure. A reduction beyond 10% is unacceptable.

- Inspect high-stress zones: Drum crossovers and anchor points are where fatigue often shows first.

- Document inspections: Consistent record-keeping helps forecast when a rope will need replacement, reducing unexpected failures.

Bedmutha supports inspections with a robust quality assurance system, enabling clients to plan maintenance scientifically.

6. Proper Storage and Handling

When not in use, ropes must be stored with care:

- Store ropes in dry, ventilated areas away from chemicals or salt exposure.

- Use pallets or reels to prevent contact with the ground.

- Cover ropes with tarpaulins to shield from sunlight and dust, but ensure air circulation to prevent condensation.

- Re-lubricate ropes before use if they’ve been stored for extended periods.

Example: Suspension bridge ropes stored incorrectly in a humid warehouse developed rust even before installation, reducing design life by 20%. Proper storage would have preserved their integrity.

7. Replacement Criteria

Recognizing when a rope has reached the end of its service life is crucial to safety:

- Excessive broken wires: If the number of broken wires exceeds safe limits, immediate replacement is required.

- Visible deformities: Bird-caging, kinks, and severe twists render a rope unsafe.

- Core failure or corrosion: Once the core is compromised, the rope loses structural integrity.

- Diameter reduction: Any reduction beyond standards means the rope has weakened significantly.

In lifting applications, using a rope beyond its safe life can have catastrophic consequences. Following international standards for replacement ensures safety and compliance.

Common Mistakes to Avoid

While best practices extend rope life, common mistakes often undo this effort:

- Using the wrong rope for the job: A general rope in mining may last weeks compared to specialized mining ropes.

- Neglecting lubrication: Dry ropes corrode internally, often invisible until sudden failure.

- Improper spooling: Loose or uneven winding causes crushing and rapid wear.

- Skipping inspections: Overlooking small signs of damage often results in catastrophic failures.

- Overloading ropes: Continuous overloading causes microfractures that shorten lifespan.

Consequences: These mistakes lead to higher costs, downtime, and severe safety risks. In some cases, failures have resulted in lawsuits, reputational damage, and loss of contracts.

Industry-Specific Best Practices

Different industries face unique challenges. Here’s how tailored practices extend rope life:

Mining & Haulage

- Challenges: Dust, abrasive rock, heavy load cycles.

- Practices: Use mining ropes with coated surfaces, perform frequent lubrication, and ensure proper spooling to resist dust intrusion.

- Case: A coal mine reduced rope failure incidents by 40% after switching to coated ropes and a strict cleaning routine.

Cranes & Elevators

- Challenges: Constant bending, shock loads, dynamic operation.

- Practices: Use specialized elevator ropes, inspect sheaves, and maintain lubrication schedules. Cranes should avoid overload cycles.

- Case: A construction firm extended crane rope service life by 25% after introducing monthly sheave inspections.

Marine & Oil & Gas

- Challenges: Saltwater corrosion, constant exposure to chemicals.

- Practices: Use marine ropes and oil & gas ropes with corrosion-resistant coatings. Lubricate frequently with anti-corrosion compounds.

- Case: An offshore platform doubled rope lifespan by switching from general ropes to HDPE-coated variants.

Suspension Bridges

- Challenges: Constant tension, weather exposure, high wind loads.

- Practices: Use suspension bridge ropes with protective coatings and schedule anchor inspections. Apply weather-resistant lubricants.

- Case: A bridge authority in Asia extended rope service life by 15 years by implementing weatherproof coatings.

Bedmutha Industries – Your Trusted Wire Rope Partner

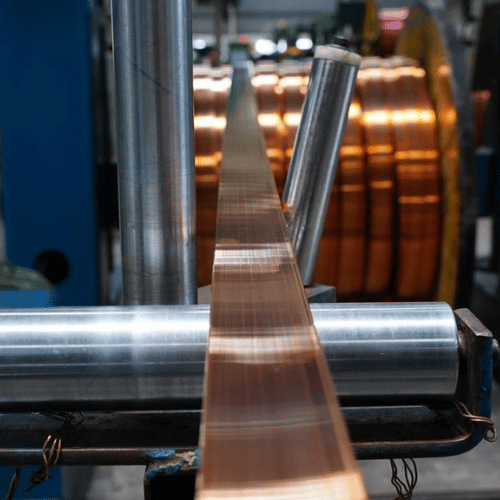

As a globally recognized manufacturer, Bedmutha Industries provides:

- A wide portfolio of steel wire ropes including non-rotating ropes, barrier ropes, and slings & fittings.

- International certificates proving adherence to global safety and quality standards.

- Custom engineering solutions for industries worldwide, tailored for unique operational challenges.

By combining superior manufacturing with best-use practices, Bedmutha ensures long-lasting performance across industries.

Conclusion

Steel wire ropes are not just industrial products — they are critical to safety, efficiency, and cost-effectiveness. By following best practices in selection, installation, lubrication, inspection, and storage, industries can maximize rope life and minimize risks. Avoiding common mistakes and adopting industry-specific measures ensures greater reliability, reduced costs, and enhanced safety.

Call to Action

Ready to choose the right rope for your project? Explore our full product portfolio and speak to our experts today:

➡️ View Our Product Range

➡️ Contact Us

Trust Sure Wire Ropes from Bedmutha Industries — where quality meets performance.