Introduction

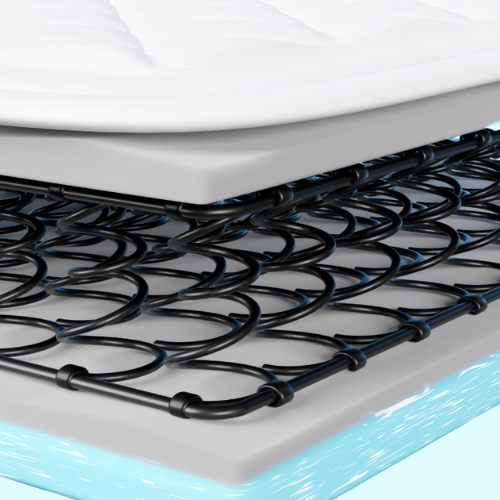

Infrastructure projects are the backbone of modern society. From the soaring sweep of suspension bridges over wide rivers to the silent rise of high-rise elevators in urban centres, the safety, reliability, and performance of these systems often hinge on one unsung hero: the steel wire rope.

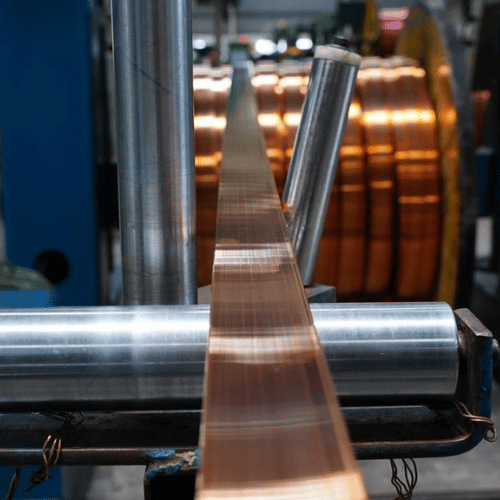

As a wire rope manufacturer in India, Bedmutha Industries prides itself on its brand Sure Wire Ropes, delivering product quality, durability, and technical excellence required for critical applications. Wire ropes not only provide structural support but also ensure safety, efficiency, and longevity in demanding environments. Their role goes beyond mechanics—they are integral to the trust people place in infrastructure every single day.

What Makes a Great Wire Rope: Key Properties

Bridges & Suspension Wire Ropes

Suspension & Stay Cables – These cables form the backbone of suspension and cable-stayed bridges, carrying dynamic and static loads with unmatched strength. They resist external forces like strong winds, traffic vibrations, and temperature variations while ensuring structural stability. The ability of wire ropes to handle millions of stress cycles makes them indispensable for long-span bridges. Their combination of flexibility and tensile strength allows them to support massive decks without compromising safety. For projects in coastal or marine zones, specialized galvanization ensures long-term durability.

Barrier & Road Ropes – Safety barriers on bridges use wire ropes as flexible yet strong protective systems. Unlike rigid concrete barriers, barrier wire ropes absorb kinetic energy during vehicle collisions, reducing impact severity and saving lives. These ropes are designed for durability, offering long service life even under constant exposure to weather. Their modular installation allows quick replacement or extension, making them a cost-effective solution. Barrier ropes combine safety, resilience, and adaptability in bridge infrastructure.

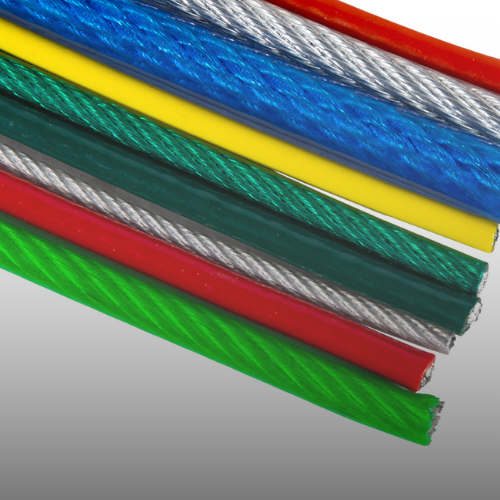

Environmental Protection – Bridges exposed to harsh environments face significant corrosion risks. To combat this, ropes are often galvanized or HDPE-coated, creating a barrier against rust and chemical damage. This is particularly vital in marine bridges and coastal highways, where humidity and salt accelerate metal deterioration. Suspension bridge wire ropes treated with coatings can function reliably for decades with minimal maintenance. By selecting corrosion-resistant designs, engineers significantly extend service life and reduce repair costs.

➡️ Explore Suspension Bridge Wire Ropes.

Elevators & Vertical Transport Wire Ropes

Hoist/Traction Ropes – Elevators rely on traction ropes to carry passengers safely between floors. These ropes must offer excellent grip and fatigue resistance while delivering smooth, silent travel. Elevator wire ropes are designed to handle constant cycles without stretching or wearing out prematurely. Their construction minimizes vibration, ensuring a comfortable experience for users. In tall buildings, the durability of traction ropes directly impacts operational efficiency and passenger safety.

Governor Ropes – Safety in elevators depends heavily on governor ropes, which are critical in preventing free fall. These ropes engage braking mechanisms when overspeed is detected, halting the elevator immediately. Their reliability is ensured through precise construction and strict quality testing. Governor ropes undergo rigorous checks to meet international safety codes, making them indispensable in vertical transport. Without them, the risk of accidents in elevators would increase drastically.

Compensating Ropes – In skyscrapers, elevator ropes grow heavier as travel distance increases. Compensating ropes balance this weight, ensuring smooth and efficient vertical transport. By offsetting uneven forces, they reduce strain on the hoisting system and improve energy efficiency. Properly engineered compensating ropes allow elevators to function reliably in the tallest buildings. Their role in distributing load evenly makes them an essential part of modern high-rise construction.

➡️ Learn more about Elevator Wire Ropes.

Other Uses of Wire Ropes in Infrastructure

Cranes & Hoists Ropes – Heavy lifting in construction, shipping, and industrial projects depends on durable crane ropes. Cranes wire ropes must endure high tensile stress while maintaining flexibility for repetitive lifting cycles. Their design minimizes fatigue and wear, enabling cranes to operate safely and efficiently. With proper lubrication and protective coatings, these ropes achieve extended service life in demanding environments. In infrastructure projects, their reliability ensures timely and safe material handling.

Mining & Haulage Ropes – Mining operations require ropes that withstand abrasive conditions and heavy loads. Mining wire ropes and haulage ropes are engineered to endure constant friction, high tension, and harsh environments underground. They enable haulage systems to transport ore and materials over long distances without frequent replacements. Their superior fatigue resistance and coating technologies make them vital for mining efficiency and worker safety. By using specialized ropes, mines reduce downtime and operational costs.

Aerial Ropeways Ropes – Ropeways provide an eco-friendly and efficient transport option in hilly regions and urban projects. Aerial wire ropes are designed to handle continuous motion, varying loads, and weather exposure. Their construction ensures passenger safety while offering smooth and stable rides. From tourism to urban transport, aerial ropeways rely on robust wire ropes to guarantee long-term reliability. With increasing focus on green transport solutions, these ropes are gaining prominence worldwide.

Why Choose Bedmutha - Sure Wire Ropes

Extensive Product Range – Bedmutha offers solutions across industries, including non-rotating ropes, marine fishing ropes, and general engineering ropes. This variety ensures that every sector—from construction to offshore—finds a rope designed for its unique requirements.

Certified Quality – Quality is central to Bedmutha’s operations. With internationally recognized certificates and stringent testing under its quality assurance system, the company guarantees compliance with global standards. Customers receive ropes that meet and exceed expectations in safety and performance.

Customization – Every project has different needs, and Bedmutha provides tailored rope diameters, tensile strengths, and coatings. This customization ensures ropes are not only fit for purpose but optimized for longevity and safety in their intended applications.

Global Standards – Manufactured in India, Bedmutha products comply with international norms, making them trusted worldwide. Explore Our Products to see the complete range designed to meet both domestic and global infrastructure needs.

Challenges & Solutions in Steel Wire Rope Use

Corrosion – Constant exposure to moisture or salt leads to reduced rope strength and premature failures. The solution lies in using galvanized or PVC/HDPE coated ropes combined with proper maintenance. Regular inspections and timely lubrication prevent rusting, extending service life and ensuring structural safety in aggressive environments.

Fatigue – Cyclic stress can weaken ropes and cause sudden failures. Engineers combat this by using non-rotating ropes and optimizing sheave designs. Bedmutha’s ropes are crafted to resist fatigue through advanced metallurgy and construction techniques. This ensures long-term reliability even under constant motion.

Abrasion – Frequent friction against surfaces leads to wear and surface damage. Abrasion-resistant designs and lubricated ropes reduce wear, extending the operational life of the system. Protective coatings add an extra layer of resilience, making ropes more durable in challenging industrial conditions.

Stretch – Excessive elongation in ropes leads to instability and safety risks. Using steel cores and pre-tensioning techniques ensures dimensional stability under heavy loads. Pre-stretched ropes from Bedmutha provide superior performance in demanding infrastructure projects.

Poor Inspection – Neglecting regular inspection increases the risk of accidents. Scheduled monitoring and preventive replacement programs help maintain safety. With proper inspection protocols, wire ropes can function reliably for years without unexpected failures.

Trends & Innovations

Non-Rotating Rope Designs – Traditional ropes can twist under load, creating operational hazards. Non-rotating ropes solve this by maintaining stability during lifting, especially in cranes and elevators. Their advanced design enhances safety and reduces downtime.

Advanced Coatings – PVC/HDPE coated ropes are designed to resist abrasion, UV radiation, and moisture. These coatings not only extend rope life but also reduce long-term maintenance costs. They are ideal for bridges, mining, and coastal applications.

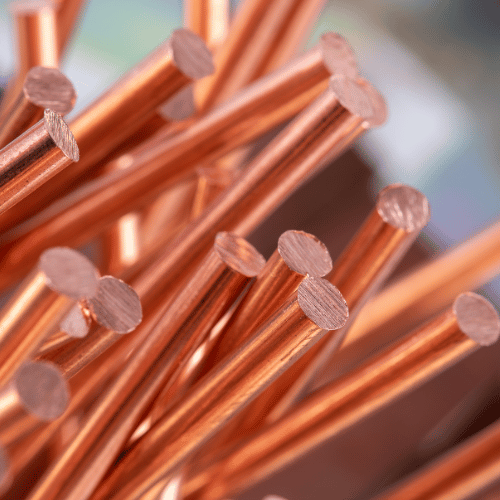

High-Strength Alloys – Using high-performance alloys allows manufacturers to create lighter yet stronger ropes. This reduces rope size while increasing load-bearing capacity, improving both efficiency and safety in modern infrastructure.

Smart Monitoring – The future of wire ropes includes embedded sensors for real-time health monitoring. IoT-enabled systems detect wear, fatigue, and corrosion before failures occur. This predictive maintenance reduces risks and improves operational uptime.

Sustainability – With growing environmental concerns, manufacturers are shifting towards recyclable steel and eco-friendly lubricants. These sustainable practices align with green building certifications and global efforts toward eco-conscious construction.

People Also Ask

What standards should I check for wire ropes in bridges?

Look for tensile strength, fatigue resistance, corrosion protection, steel cores, and certifications. International standards like ISO, EN, or BIS ensure reliability and safety.

How are elevator ropes different from bridge ropes?

Elevator ropes face frequent movement cycles, demanding high fatigue resistance and smooth operation. Bridge ropes, in contrast, handle static loads while resisting environmental stresses like humidity and salt.

Why do wire ropes fail?

The most common causes include corrosion, fatigue, abrasion, overloading, and poor inspection practices. By choosing high-quality ropes and following preventive maintenance, failures can be significantly minimized.

Conclusion & Call to Action

Wire ropes are the silent backbone of modern infrastructure—supporting bridges, enabling elevators, and ensuring safe, reliable systems. Their strength, durability, and advanced engineering make them indispensable in today’s world. Choosing the right manufacturer is crucial for long-term performance and safety.

➡️ Explore our Product Range for detailed categories.

➡️ Visit our Contact Page to discuss your wire rope needs or request a quote.