Selecting a reliable wire rope manufacturer is a critical decision that can significantly impact operational safety, equipment longevity, and overall project performance. In industries such as construction, mining, marine, and elevator systems—where precision, strength, and endurance are non-negotiable—it is essential to evaluate manufacturers on multiple fronts. These include material quality, compliance with standards, engineering support, and long-term service reliability.

Here are 10 essential checks to consider before finalizing your wire rope supplier.

Compliance with Standards & Certifications For Wire Ropes

- Indian Standards (IS): Check whether the wire rope manufacturer complies with the relevant Indian Standards (e.g., IS 2266 for general engineering ropes, IS 1855 for mining ropes, etc.). These set benchmarks for dimensions, breaking strength, and construction.

- Bureau of Indian Standards (BIS) / ISI Mark: Manufacturers should have a valid BIS license for the product types and carry ISI or standard marks. Given the new Steel Wire Rope Quality Control Order (QCO), this is increasingly mandatory.

- International Standards: If your project has international or export components, ask about ISO, BS, ASTM standards compliance. Manufacturers serving sectors like marine, oil & gas, or bridges often adhere to multiple standard regimes.

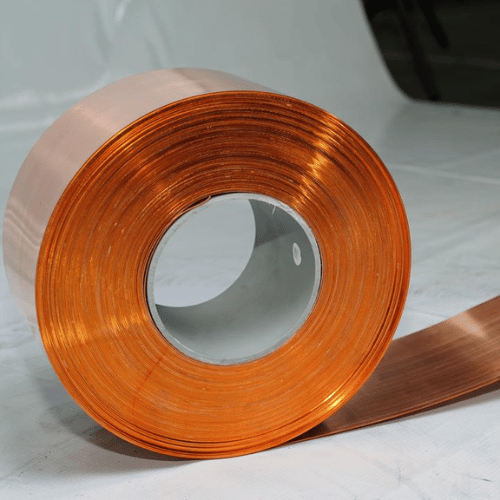

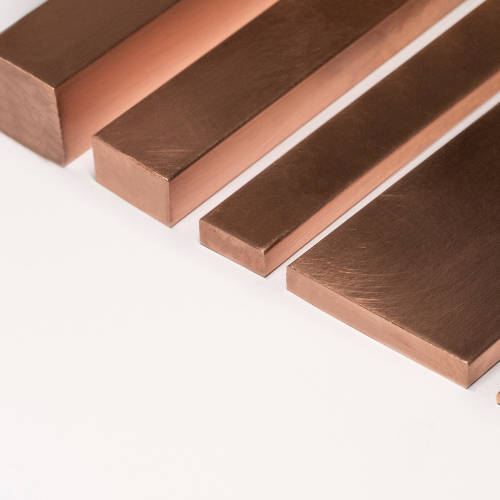

- Raw Material & Wire Quality for Wire Ropes

- Wire Material: Type of steel, grade, tensile strength of wires used. The quality of the individual wires directly impacts durability, flexibility, fatigue resistance, etc.

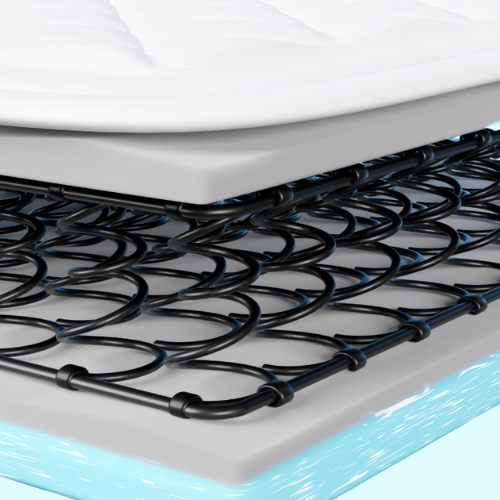

- Core Material: Steel core vs fibre core. The core type affects flexibility, strength, and performance in specific environments (e.g. heat, moisture, dynamic loads).

- Chemical Composition & Treatment: Steel wire treatments (galvanizing, coatings, alloying) to impart corrosion resistance or special properties.

- Wire Rope Construction & Design (Lay, Strand, Diameter)

- Construction Type: E.g. 6×19, 6×37, 19×7, 8×19, etc. (the number of strands, wires per strand, etc.). Different constructions suit different applications (abrasion, fatigue, flexibility).

- Lay and Rotation: Regular lay vs Lang lay or alternate lay; right‑ or left‑hand lay. The lay affects how rope behaves under bending and dynamic loads.

- Diameter & Tolerance: Accurate diameters are crucial for compatibility with sheaves, drums, pulleys. Tolerance limits should be tight per standard.

- Mechanical Properties: Strength, Fatigue & Load Attributes of Wire Ropes

- Minimum Breaking Load / Tensile Strength: Manufacturer should supply data and proofs. The rated breaking load must match or exceed your design requirement plus safety margin.

- Fatigue Life / Dynamic Load Performance: If the rope will undergo repeated load cycles, oscillation, or bending over sheaves, fatigue resistance is key.

- Elasticity / Stretch: How much rope stretches under load; for some applications (elevators, precision lifting) low elongation is needed.

- Corrosion Resistance & Environmental Suitability

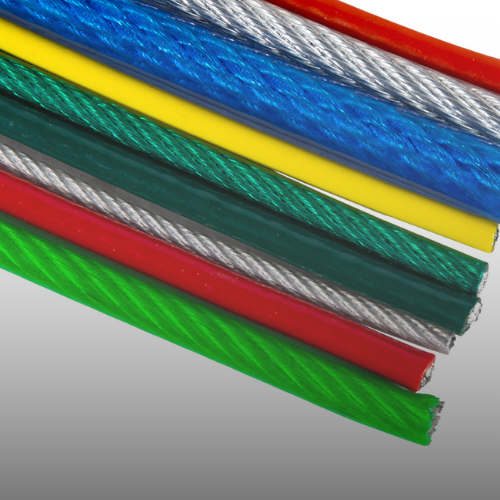

- Coatings or Platings: Galvanising, HDPE/PVC coatings, specialized corrosion resistant alloys if needed.

- Environmental Conditions: Is the rope going to be used in marine (salt water), oil/gas, high humidity, high temperature, or highly abrasive conditions? This determines the required finish.

- Lubrication & Maintenance: Whether the manufacturer pre‑lubricates, supplies ropes with internal lubricants, or gives guidance on ongoing maintenance.

- Quality Assurance & Testing Facilities

- In‑house Testing & Lab Capabilities: Tensile tests, fatigue tests, breaking load tests, wire & strand inspection, non‑destructive testing, etc.

- Third‑party / Independent Test Reports: If possible, check if the rope can be tested independently or certified by external labs.

- Traceability: Ability to trace raw material batches, production batches, test records. Ensures accountability if there is a failure.

- Manufacturing Capacity & Lead Time Reliability

- Production Capacity: Does the manufacturer have sufficient capacity (machinery, manpower, plant size) to fulfill your orders on time?

- Custom vs Standard Products: If you need custom rope (special construction, coatings, fittings), can they make to order? What is their turnaround?

- Consistency & Delivery Track Record: Past performance matters. Timely deliveries, consistency in product quality across batches.

- Service & Support: Fittings, Repairs, Replacement, Advice

- Fittings and Accessories: Availability of slings, end fittings, swages, clamps, terminations, etc. If a rope comes without compatible fittings, extra cost and risk.

- Technical Support: Engineering guidance on rope choice, installation, maintenance, inspection. A manufacturer who helps you select the right rope saves costs and risk downstream.

- After‑sales & Spare Parts: Availability of spare rope sections, replacements, and support in case of failures.

- Reputation, References & Industry Experience

- Track Record / Years in Business: More years typically mean more experience dealing with diverse problems.

- Relevant Industry Experience: If your requirement is for marine, elevators, mining, suspension bridges, forestry, etc., select a manufacturer who has proven work in that specific segment.

- Customer References and Case Studies: Can they show installations, client testimonials, failure analyses, or usage examples?

- Cost vs Total Lifecycle Value

- Initial Price vs Total Cost of Ownership: Sometimes cheaper ropes cost more in frequent replacements, maintenance, downtime. Higher‑quality wire ropes with better coatings, better core, or treated wires may cost more upfront but save money.

- Warranty / Guarantees: How long does the guarantee cover issues like wire breaks, corrosion, fatigue? What are the terms?

- Transport & Logistics Costs: Consider freight, handling, packaging—and whether the manufacturer has efficient & safe dispatch. For big or heavy orders, shipping cost can become large.

Bedmutha’s Edge: What Makes Sure Wire Ropes Stand Out

To help you see what to expect when selecting a top‑tier wire rope manufacturer in india, here are what you should look for—and what Bedmutha Industries provides:

- Wide range of rope types and applications: general engineering, cranes, elevators, marine, oil & gas, forestry, suspension bridges, slings & fittings. (See product pages: Wire Ropes, Mining, Elevators, etc.)

- Certification & Quality Assurance: Bedmutha maintains strict adherence to standards, excellent QA systems. (You may want to look up their Certificates and Quality Assurance System.)

- Technical guidance: Helps customers select rope constructions, suitability (e.g. diameter, lay, core), suited for environmental conditions.

- After sales and support: Fittings, spare parts, etc., supported through product range like Slings & Fittings.

Frequently Asked Questions (FAQs)

| Question | Answer |

|---|---|

| What is the difference between IS 2266 and IS 2408 standards? | IS 2266 covers steel wire ropes for general engineering purposes (lay, breaking strength, constructions). IS 2408 is a broader standard that may apply under recent Quality Control Orders to ensure compliance in manufacturing & labelling for steel wire ropes and strands etc. Always check which version is currently applicable. |

| How do I know what rope construction is best for my application? | Consider factors like load type (static vs dynamic), bending over drums/sheaves, environmental stresses (corrosion, abrasion), length of span, required flexibility, and lifespan. Rope constructions with more wires per strand tend to have better fatigue and abrasion resistance; those with smaller number of wires per strand may be stiffer but more durable under certain loads. |

| Why is the core type important (steel vs fibre)? | Fibre cores (natural or synthetic) give better flexibility and shock absorbance; steel cores offer higher stiffness, less elongation, and better support in high temperature / heavy load. The environment (heat, moisture) and load cycles decide the better choice. |

| What inspection criteria should I use during usage? | Visual inspection for broken wires, kinks, corrosion, diameter reduction, damage by fittings/sheaves, lubrication condition. Also periodic detailed inspections / non‑destructive testing, as applicable. Follow standards and guidelines relating to specific sectors. |

| How often should ropes be replaced or discarded? | There isn’t a universal lifespan—it depends on usage, load, environment, maintenance. But criteria like excessive broken wires, corrosion, reduction in diameter beyond tolerance, loss of strength, or safety margin failing are signals. Manufacturer’s guidelines + on‑site monitoring are key. |

Conclusion

Choosing the right wire rope manufacturer is more than just comparing prices. It involves evaluating standards, raw materials, rope design, fatigue behavior, environmental suitability, QA & testing, service, reputation, and lifecycle value.

If you want steel wire ropes that deliver in safety, performance, durability—and you want full transparency and support—Sure Wire Ropes by Bedmutha Industries ticks all those boxes.

View our full Product Range and explore specific application rope types (mining, elevators, marine, etc.). If you have specific requirements or need expert advice, don’t hesitate to Contact Us today. Let’s find the perfect wire rope solution for your needs.