Introduction – Why the manufacturing process matters

Every wire rope starts with a single strand of steel — but what happens next defines its strength. In this guide, we’ll unravel the step-by-step process followed by leading manufacturers of wire ropes in India, and see how technology and testing turn raw steel into a lifeline for industries. Choosing the right manufacturer is critical for safety, durability, and performance, especially in high-stakes sectors like mining, oil & gas, elevators, and infrastructure.

India has emerged as a global hub for wire rope production, with advancements in metallurgy, engineering, and automation transforming how ropes are manufactured. Let’s dive deep into each stage of the process — from raw steel to tested and certified ropes — to understand how Indian manufacturers like Bedmutha Industries set new benchmarks in quality.

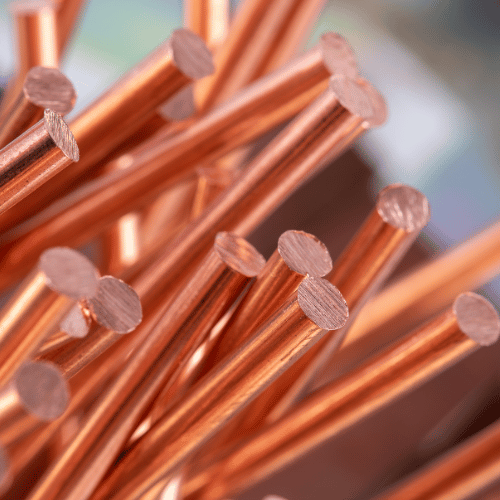

Step 1 – Raw material selection and wire drawing

The first key stage in the wire rope manufacturing process India is the sourcing of appropriate steel wire rods and their conversion into drawn wires. Manufacturers pick high-grade steel, often in the form of rods or billets that meet specific chemical and mechanical criteria.

After pickling (to remove scale) and patenting (to refine microstructure), the steel rod is drawn through a sequence of dies to create wires of required diameters. The wire drawing process significantly influences the rope’s tensile strength and fatigue life.

Key Steps in Wire Drawing:

- Material selection: High-carbon steel with consistent chemistry (typically C60 to C82 grade) is preferred.

- Descaling and cleaning: Oxide layers are removed through acid pickling.

- Pre‑Drawing: The steel rod is passed through larger dies for initial diameter reduction, relieving surface defects to prepare for main stage drawing.

- Patenting: Heat treatment that refines grain structure, enhancing ductility and fatigue resistance.

- Multi-pass drawing: The wire is pulled through progressively smaller dies, reducing diameter while increasing tensile strength.

- Lubrication during drawing: Prevents wire surface damage and maintains dimensional accuracy.

The drawn wires are then coated or lubricated, depending on their end-use. The quality of this stage directly impacts the rope’s performance, particularly in dynamic load environments like cranes or elevators.

The first key stage in the wire rope manufacturing process India is the sourcing of appropriate steel wire rods and their conversion into drawn wires. Manufacturers pick high-grade steel, often in the form of rods or billets that meet specific chemical and mechanical criteria.

After pickling (to remove scale) and patenting (to refine microstructure), the steel rod is drawn through a sequence of dies to create wires of required diameters. The wire drawing process significantly influences the rope’s tensile strength and fatigue life.

Key Steps in Wire Drawing:

- Material selection: High-carbon steel with consistent chemistry (typically C60 to C82 grade) is preferred.

- Descaling and cleaning: Oxide layers are removed through acid pickling.

- Pre‑Drawing: The steel rod is passed through larger dies for initial diameter reduction, relieving surface defects to prepare for main stage drawing.

- Patenting: Heat treatment that refines grain structure, enhancing ductility and fatigue resistance.

- Multi-pass drawing: The wire is pulled through progressively smaller dies, reducing diameter while increasing tensile strength.

- Lubrication during drawing: Prevents wire surface damage and maintains dimensional accuracy.

The drawn wires are then coated or lubricated, depending on their end-use. The quality of this stage directly impacts the rope’s performance, particularly in dynamic load environments like cranes or elevators.

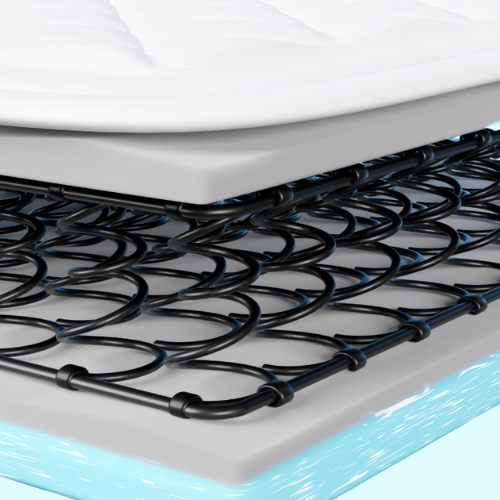

Step 2 – Stranding and closing of wires

Once wires are drawn, they are grouped into strands and then twisted (“closed”) to form the final rope. This is the stage where geometry, construction type, and precision come into play.

Stranding Process:

- Multiple wires (typically 7, 19, 36, or more) are twisted around a central core (steel or fibre).

- The strand formation must maintain equal tension and uniform lay length to ensure rope balance.

Closing Process:

- Several strands are twisted together in the opposite lay direction to form a rope.

- Rope constructions vary (6×19, 6×36, 8×19, 18×7, etc.) depending on flexibility, strength, and rotational stability.

Core Types:

- Fibre Core (FC): Offers flexibility but less strength.

- Independent Wire Rope Core (IWRC): Adds strength and crush resistance.

- Wire Strand Core (WSC): Used in small diameter ropes.

This stage is critical for applications that demand specific structural integrity. Manufacturers like Bedmutha use modern stranding machines that provide tension control, lay correction, and online monitoring.

Step 3 – Lubrication and galvanizing process

Protection and longevity are the focus here. Proper lubrication and coating processes improve fatigue life, corrosion resistance, and handling.

Lubrication:

- Applied at stranding and closing stages.

- Types: Mineral oil-based, synthetic, and biodegradable lubricants.

- Reduces internal wire friction during bending and operation.

Galvanizing:

- Zinc-coated wires are used for marine, fishing, construction, and infrastructure applications.

- Hot-dip or electro-galvanizing protects wires from rust.

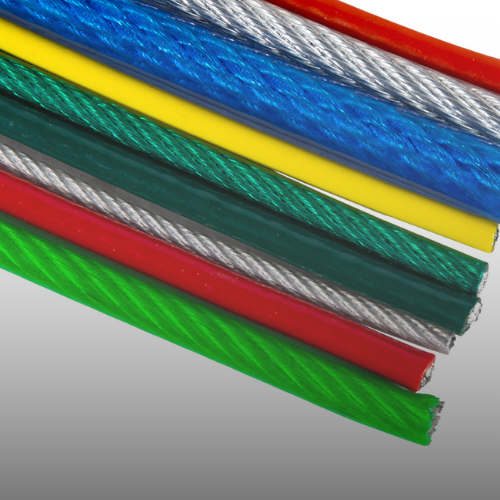

Plastic Coatings:

- PVC/HDPE coatings insulate wires against abrasion, UV, and chemicals.

- Used in suspension bridges, fencing, marine applications, and electrical hoists.

- See Bedmutha’s PVC/HDPE Coated Rope Range.

These steps are essential in extending service life, especially in aggressive environments.

Step 4 – Testing for breaking load and elongation

A rope’s reliability lies in its proven strength. Reputable manufacturers implement stringent quality control and testing protocols at this stage.

Key Tests:

- Breaking Load: The rope is pulled to its failure point to verify it meets or exceeds rated capacity.

- Elongation: Evaluates how much the rope stretches under load, critical for elevators and precision lifting.

- Fatigue Testing: Simulates repeated bending cycles to test endurance, especially important for mining and cranes.

- Torsion and Bending: Tests resistance to twisting and bending under load.

- Corrosion Resistance: Especially for galvanised or coated ropes.

- Magnetic and Visual Inspection: Ensures no internal breaks or surface flaws.

All results are documented in traceable certificates. Bedmutha’s QA labs are equipped with state-of-the-art tensile and fatigue testing equipment, ensuring compliance with IS, ISO, and client-specific standards.

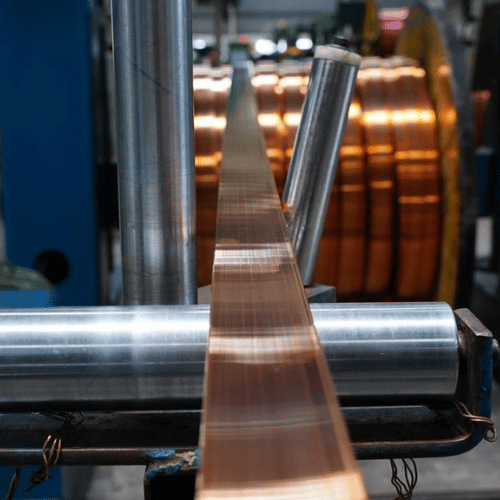

Modern automation in Indian manufacturing plants

Today’s wire rope manufacturing in India is not limited to manual methods. Automation and digitalization play a major role in improving quality, consistency, and scalability.

Automation Highlights:

- Servo-Controlled Machines: Ensures tension, pitch, and lay uniformity.

- PLC-Based Systems: Enables real-time monitoring and error detection.

- Online Diameter Monitoring: Ensures wires and strands are within precise tolerances.

- Auto-Lubrication Systems: Deliver consistent coating and reduce waste.

- Digital SPC (Statistical Process Control): Monitors variations and improves process stability.

- In-House Software Systems: Manage batch traceability, testing records, and order history.

Indian players like Bedmutha have embraced Industry advance technologies in their rope manufacturing plants to deliver global-quality products consistently.

Why Bedmutha’s process ensures consistency

Bedmutha Industries stands out in India’s wire rope sector due to its comprehensive and quality-driven approach.

Key Differentiators:

- Integrated Operations: From wire drawing to rope testing under one roof.

- Diverse Product Portfolio: Mining, Cranes, Elevators, Marine, Suspension Bridges, Oil & Gas.

- Global Certifications: ISO 9001, 14001, 45001, IATF 16949.

- Robust R&D: New construction development, application-specific designs.

- Export-Ready Compliance: Supplied to 21+ countries with global documentation standards.

Sure Wire Ropes — Bedmutha’s premium brand — is engineered for maximum safety, longevity, and performance across sectors.

- Integrated Operations: From wire drawing to rope testing under one roof.

Conclusion – Precision that builds trust

The wire rope manufacturing process India has evolved into a high-precision engineering workflow. Each phase — from selecting the right grade of steel, through drawing, stranding, lubrication, coating, testing, and automation — adds value and ensures safety.

For decision-makers in mining, infrastructure, marine, cranes, and oil & gas, choosing the right manufacturer means more than just price. It’s about quality assurance, product traceability, application-specific performance, and long-term support.

With Bedmutha Industries, you get more than a product — you get a partner committed to manufacturing excellence, certified processes, and solutions tailored to your needs.

Take the next step: Contact us or explore our full range of precision-engineered wire ropes today.