Introduction – Why choosing the right manufacturer matters

Choosing a reliable wire rope manufacturer in India is not just about price — it’s about safety, performance, and long-term trust. Every strand that lifts, anchors, or supports critical infrastructure depends on the quality built at the plant. Whether it’s hauling ore in mining, lifting heavy loads in a crane, or keeping an elevator moving smoothly, failure of the wire rope can mean costly downtime, safety risks or worse. Let’s understand what truly defines a dependable manufacturer and how you can identify one.

Core factors that define trust and quality

Raw-material purity and IS standards

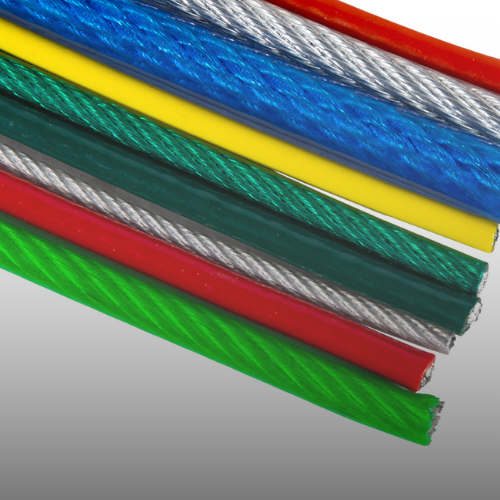

A trusted manufacturer sources high-grade raw material and adheres to relevant Indian Standards (IS) and international benchmarks. For example:

- Use of high-tensile steel wires, correct carbon and alloy composition, consistent wire drawing and patenting processes.

- Compliance with standards such as IS 2266 (General Engineering Ropes), IS 2365 (Elevator Ropes) and IS 1835 (Roping Wire).

- Traceability of wire batches, documented raw material certificates, and control of impurities are essential.

Why this matters: If the wire’s core steel lacks uniformity or allowable defects, the finished rope will have weak links, fatigue failure or poor service life.

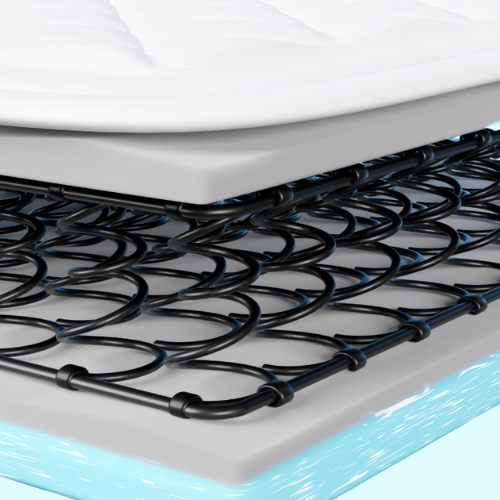

Advanced manufacturing process (Stranding and Closing)

The manufacturing of steel wire ropes is more than twisting wires together. Key technical features include:

- Precise stranding geometry: core (steel fibre, IWRC – independent wire rope core, or WSC) and outer wires configured correctly.

- Proper lubrication, pre-forming, core assembly, compaction, and correct rope lay length.

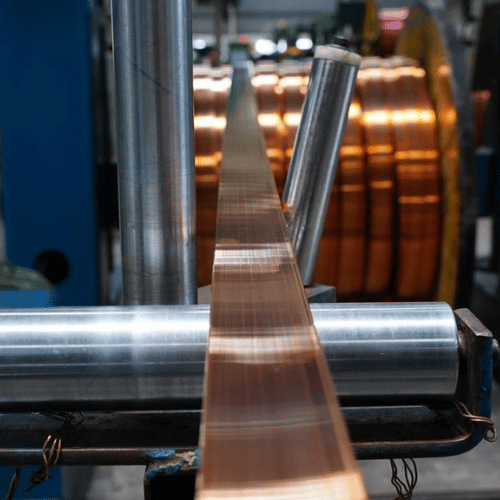

- Use of modern rope-making machinery (often imported), and plant infrastructure capable of large-diameter, non-rotating or coated ropes.

- Manufacturing versatility: producing ropes for mining, marine, cranes, elevators, oil & gas etc requires different constructions.

A manufacturer that invests in advanced production shows they are serious about quality and innovation — not simply low-cost commodity supply.

Testing and certification compliance

Trustworthy manufacturers do not rely simply on internal promises. They build testing and certification infrastructure:

- Fully equipped labs for tensile tests, fatigue cycles, breaking load tests.

- Certifications such as ISO 9001, ISO 14001, ISO 45001, IATF 16949 (for automotive) add external credibility.

- Material test certificates, rope test certificates and conformity with client-/industry-specific standards.

- Transparency in test reports, third-party audits, and supply-chain traceability.

In short: the manufacturer’s claims must be backed by independent verification. Without this, you’re buying risk, not rope.

Track record of supplying critical industries

The ultimate proof of trust: a manufacturer that serves demanding industries. Features to check:

- References and supply history in mining, oil-gas, marine, heavy-lift cranes, elevators.

- Export capability – supply outside India shows capability to meet international standards.

- Long-standing presence and stable operation.

- Case studies or testimonial evidence of performance under heavy duty.

For procurement managers, seeing that the rope manufacturer’s product has been trusted in high-stakes projects (mining winders, bridge cables, oil drilling rigs) is huge.

How to evaluate a manufacturer before you buy

Site visits and third-party inspection

Before you finalize a purchase from a “wire rope manufacturer in India”, follow these steps:

- Visit the actual manufacturing facility if possible. Check the cleanliness, layout, machine condition, stock of raw wires, documentation.

- Ask for a plant tour: view the rope-making machines, lab area, quality control section.

- Engage a third-party inspector (e.g., independent lab) to audit the facility or inspect the lot.

- Verify the manufacturer’s certifications and ask for certificate copies.

- Check sample rope constructions, confirm they match your spec (core type, lay, diameter, coating).

This kind of audit separates manufacturers that make “good sales talk” from those that deliver performance.

Checking tensile and fatigue reports

When you have shortlisted manufacturers (one of them being Bedmutha), ensure you get detailed test reports:

- Breaking load (nominal and actual) vs the spec. Some manufacturers over-rate.

- Fatigue test results (cycles to failure) for hoist/dragline ropes especially.

- Wear and abrasion resistance test results if used in mining or marine environments.

- Certification of material (wire tensile strength, elongation, core type, grade).

- Traceability: batch/lot number of wires, date of manufacture, and relation to rope test report.

- After you receive the rope, check documentation: certificate of manufacture, test report, inspection report, shipping/factory issue.

By doing due diligence you ensure you’re working with a rope from a trustworthy manufacturer rather than a commodity supplier.

The Bedmutha Advantage

As you evaluate potential vendors, consider the specific strengths of Bedmutha Industries as a wire rope manufacturer in India:

- Established in 1988 and part of Bedmutha Group, Bedmutha has a strong legacy in steel wire and wire ropes.

- The company holds certifications like IATF 16949, ISO 9001, ISO 14001 & 45001, showing commitment to quality, environment and safety.

- Wide product range tailored to multiple industries: mining (dragline, shovel, hoist ropes); elevators, marine, construction, oil & gas etc via dedicated sub-pages.

- Export to 21+ countries, showing ability to meet global standards and logistics.

- Advanced manufacturing infrastructure: recent expansion, state-of-the-art machines, ability to produce large capacities.

- End-to-end service: from selection guidance, testing, documentation, global supply chain.

For procurement managers, the combination of legacy, certifications, breadth of application and export footprint make Bedmutha a strong candidate when you’re choosing a trusted manufacturer of steel wire ropes.

Conclusion – Choose reliability built strand by strand

When you’re selecting a wire rope manufacturer in India, cost is only one variable. What truly matters is safety, performance, durability and peace of mind. By focusing on these four pillars — raw material excellence, advanced manufacturing, rigorous testing/certification and proven track record — you minimise risk.

With Bedmutha Industries and its “Sure Wire Ropes” brand, you have a manufacturer that ticks all the boxes: trusted legacy, certified systems, wide industry coverage and export credentials.

Take the next step today: Contact us for a quote or visit our product range Steel Wire Ropes to explore solutions for mining, cranes, elevators, marine, oil & gas and beyond — and make a choice you can trust, built strand by strand.