Introduction

Wire ropes are the backbone of heavy-duty lifting, transportation, structural stability, and safety in critical sectors like mining, infrastructure, oil & gas, and construction. At Bedmutha Industries, a leading steel wire rope manufacturer in India, we engineer precision-grade ropes for a wide range of industrial and infrastructure applications across the globe.

Whether it’s lifting loads in cranes, carrying passengers in elevators, or stabilizing suspension bridges, wire ropes must meet exacting strength and durability standards. In this guide, we explore the top applications of Bedmutha wire ropes, each engineered to serve demanding industrial needs.

Why Choose Bedmutha Wire Ropes?

- India-based global manufacturer with decades of experience

- Wide portfolio: haulage, cranes, aerial, oil & gas, mining, marine, and more

- High-tensile strength, corrosion resistance, non-rotating, and coated variants

- Trusted by leading infrastructure and engineering firms

Top 10 Industrial & Infrastructure Applications of Wire Ropes

- Haulage Ropes

- Aerial Ropeways

- Mining Ropes

- Crane and Hoist Ropes

- Elevator and Lift Ropes

- Forestry and Logging

- Suspension Bridges

- Oil & Gas Industry

- Slings & Fittings

- Specialized Applications

- General Engineering: Used in OEMs, conveyors, and mechanical systems where consistency and performance matter.

- Marine & Fishing: Saltwater-resistant ropes designed for trawling, mooring, and netting. Our ropes ensure safety and resilience in harsh maritime conditions.

- Non-Rotating Ropes: Ideal for lifting operations where spin-free operation is vital, enhancing accuracy and safety during critical lifts.

- Barrier Wire Ropes: Used in highway and military barricades to absorb impact and protect lives. Built to withstand force and environmental wear.

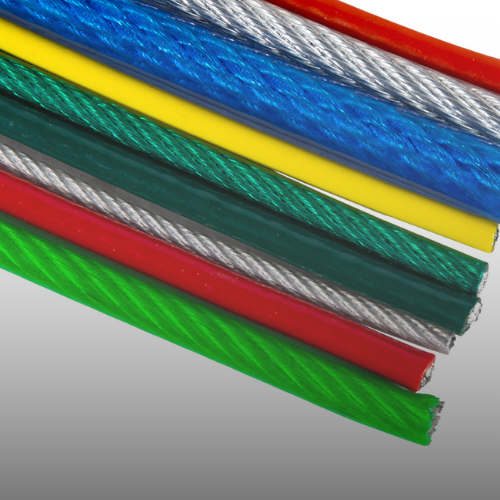

- PVC/HDPE Coated Ropes: For extended life and environmental resistance, especially in corrosive or wet environments. These coatings enhance durability and reduce maintenance costs.

Technical Highlights

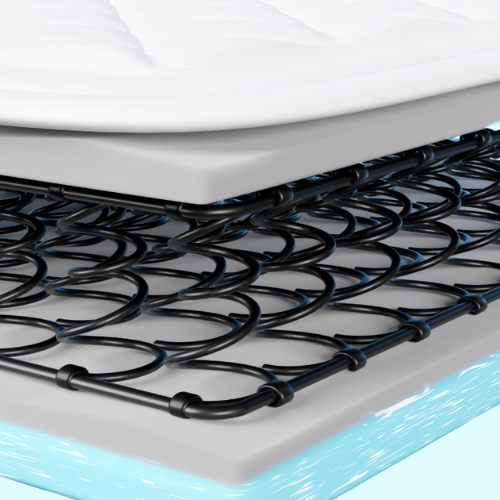

- Construction: Multiple strands wound around a core (fiber or steel)

- Types: Galvanized, ungalvanized, stainless steel, coated ropes

- Features: High breaking load, kink resistance, and low elongation

- Standards: IS, BS, ASTM, ISO compliance for quality assurance

Why Applications Differ by Industry

Each industry demands different performance from wire ropes:

- Mining: Abrasion and fatigue resistance

- Elevators: Flexibility and silent operation

- Oil & Gas: Corrosion-proof and pressure-tolerant

- Marine: Saltwater resistance and non-slip handling

Choosing the right rope impacts operational safety, efficiency, and long-term cost.

People Also Ask

Q: What are wire ropes used for in industrial applications?

A: Wire ropes are used for lifting, pulling, hoisting, securing, and stabilizing heavy loads in industries like mining, construction, marine, oil & gas, and elevators.

Q: What type of wire rope is best for elevators?

A: Steel wire ropes with high flexibility and fatigue resistance are ideal for elevators, especially those used in high-rise buildings.

Q: Are non-rotating wire ropes better for cranes?

A: Yes. Non-rotating ropes reduce spin during lifting, improving safety and precision in crane operations.

Q: Can wire ropes withstand harsh environments?

A: Yes, especially coated or stainless steel variants that resist corrosion, extreme temperatures, and heavy loads.

Contact Bedmutha Industries

Looking for a trusted steel wire rope manufacturer in India for your next project?

✅ Contact Us

✅ Download Our Product Brochure

✅ Explore our full Wire Rope Product Range

Trust Bedmutha Industries for globally recognized quality, tailored rope solutions, and unmatched service.

Conclusion

Steel wire ropes remain indispensable across a wide spectrum of industries in India. With innovation, precision, and performance at its core, SURE Wire Ropes by Bedmutha Industries stands tall as one of the top steel wire rope manufacturers in India.

Whether your application is mining, construction, marine, or beyond—there’s a SURE solution designed for you.