Introduction

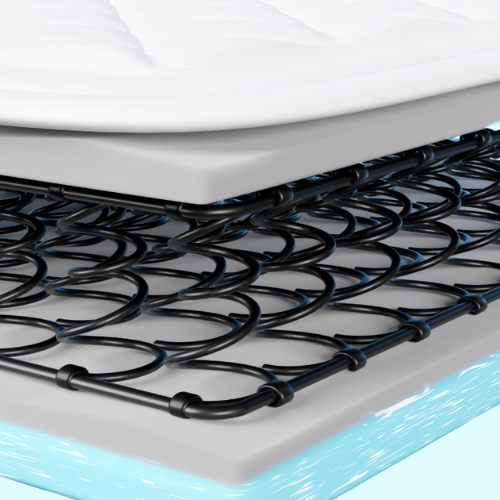

Understanding Wire Rope Construction

- Wire Rope Basics

- Core Types

- Fiber Core (FC): Offers flexibility and better lubrication retention. Ideal for light-duty applications.

- Independent Wire Rope Core (IWRC): Provides enhanced strength and resistance to crushing. Preferred for demanding tasks.

- Lay Direction

- Regular Lay: Strands and wires are twisted in opposite directions, making the rope more stable and less likely to untwist.

- Lang Lay: Strands and wires run in the same direction, increasing flexibility and wear resistance, but requiring careful handling.

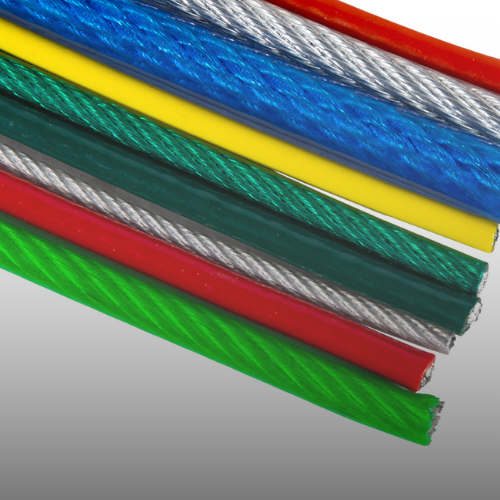

- Material and Coatings

- Bright (Uncoated): Suitable for indoor, dry conditions.

- Galvanized: Adds corrosion resistance for general outdoor use.

- Stainless Steel: High corrosion resistance; essential for marine or chemical environments.

- PVC/HDPE Coated: Adds abrasion and chemical protection for specialized settings.

Key Selection Criteria

- Load Capacity and Safety Factor

Determine your maximum operating load and apply an appropriate safety factor, generally 5:1 or more depending on application and industry standards.

- Abrasion vs. Fatigue Resistance

- Abrasion Resistance: Ropes with fewer, thicker wires are more resistant to external wear.

- Fatigue Resistance: Ropes with more, thinner wires are better for repetitive bending and winding.

- Environmental Suitability

- Marine & Coastal: Opt for galvanized or stainless ropes to combat saltwater corrosion.

- Industrial & Mining: Choose ropes designed for abrasion and mechanical stress.

- Elevators & Cranes: Consider rotation-resistant ropes to maintain load stability.

- Rotation Resistance

Non-rotating ropes are essential in vertical lifting to prevent dangerous spinning and enhance control.

- Standards and Certification

Verify that the rope complies with national and international standards such as IS 3973, ISO, or EN to ensure performance and safety.

Additional Tips to Choose the Right Wire Rope

- Consider Rope Diameter and Tolerance

The diameter of your wire rope must be compatible with the pulleys and sheaves in your application. Incorrect sizing can lead to premature wear or system failure.

- Evaluate Rope Flexibility

Flexibility matters, especially in applications requiring repeated winding and unwinding. Constructions like 8×25 or 6×36 offer superior flexibility compared to 6×19.

- Review Application Frequency

Frequent or continuous-use applications require ropes with high fatigue resistance and internal lubrication. Infrequent use may allow for more cost-effective selections.

- Assess Compatibility with End Fittings

Ensure your rope selection supports the correct termination methods like sockets, clamps, or thimbles. Mismatched fittings can compromise strength.

- Inspect Service Environment

Heat, moisture, chemicals, and UV exposure all affect rope performance. Match your rope’s material and coating to the environment for maximum lifespan.

- Plan for Maintenance

Choose ropes with visible outer wire wear indicators or ones that allow easy lubrication. This helps with timely maintenance and extends rope life.

Application-Based Recommendations

| Application | Recommended Rope | Key Features |

|---|---|---|

| Cranes | 6×36 IWRC Compacted | Fatigue resistance, high tensile strength |

| Elevators | Rotation-Resistant IWRC | Smooth and safe vertical operation |

| Marine & Fishing | Galvanized/Stainless FC | Excellent corrosion resistance |

| Mining & Haulage | Galvanized 8×25 IWRC | Durability and abrasion resistance |

| Suspension Bridges | Locked-Coil or Non-Rot. | Stability and minimal stretch |

| Forestry | 6×19 or 6×36 FC | Flexibility and ease of handling |

Summary Checklist for Choosing Wire Ropes

- Determine operating load and apply proper safety factor

- Decide between abrasion resistance and fatigue resistance

- Choose between IWRC and FC based on application

- Select appropriate material and coating

- Check rotational requirements

- Match rope diameter with system components

- Review environment and maintenance needs

- Ensure compliance with relevant standards

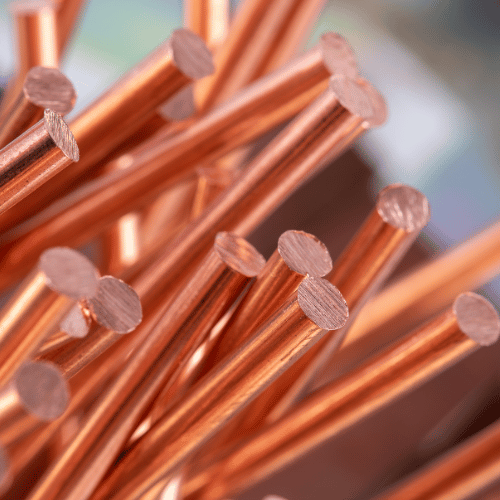

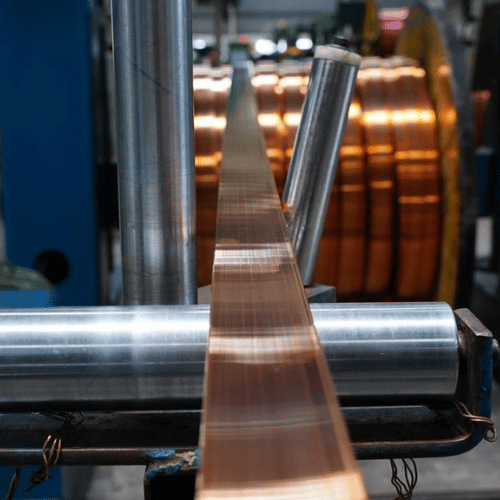

Conclusion: Trust India’s Leading Steel Wire Rope Manufacturer

Wire rope selection involves both technical evaluation and practical judgment. For projects requiring durability, safety, and proven performance, partnering with a trusted manufacturer is key.

Bedmutha Industries, under the brand Sure Wire Ropes, is widely recognized among the top wire rope manufacturers in India. As one of the largest wire rope manufacturers in India, Bedmutha delivers precision-engineered steel wire ropes tailored for a wide range of applications.

Whether you need corrosion-resistant marine ropes, fatigue-resistant crane ropes, or heavy-duty mining ropes, Bedmutha is your go-to wire rope manufacturer in India.

Explore our specialized solutions:

Choose Sure Wire Ropes from Bedmutha—the best wire rope company in India committed to performance, reliability, and innovation.

Contact us today or view our complete product range to get started.